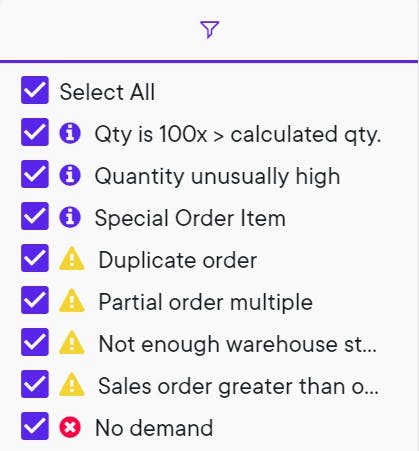

AGR's Order Exception flags provide a comprehensive overview of orders that may demand special attention. Whether it's due to quantity discrepancies or unique circumstances, these flags act as your guide to reviewing orders by granting instant insights into why a particular order needs a review.

Unusually High Quantity

If an ordered quantity significantly exceeds the average of the last 10 orders, AGR highlights this exception. Such insights allow you to quickly identify and address unusual ordering patterns.

Excessive Quantity Alert

When the calculated quantity surpasses the suggested order quantity by 100 times due to factors like minimum order quantity or order multiples, AGR raises this flag. You retain the control to amend the quantity according to your preferences.

Special Order Item Notification

For special order items, AGR extracts demand from open sales orders rather than future projections. This exception serves as a reminder that the demand originates from existing orders, ensuring accurate order proposals.

Duplicate Order Caution

When the same item appears multiple times in active orders for the same location, AGR alerts you to avoid unintentional duplication, promoting order accuracy.

Partial Order Multiple Advisory

If an order quantity doesn't align with the standard order multiple, AGR's flagging indicates a potential mismatch. This often results from manual quantity adjustments, prompting a review for consistency.

Insufficient Warehouse Stock Notification

In scenarios involving warehouse replenishment, this exception points out instances where warehouse stock can't fulfil orders from all locations. It helps you navigate supply challenges when fulfilling orders.

Sales Order vs. Order Quantity Discrepancy

When a sales order quantity exceeds the calculated order quantity and "Never" Sales Orders setting is active, AGR prompts you to adjust the order quantity, ensuring accurate fulfilment.

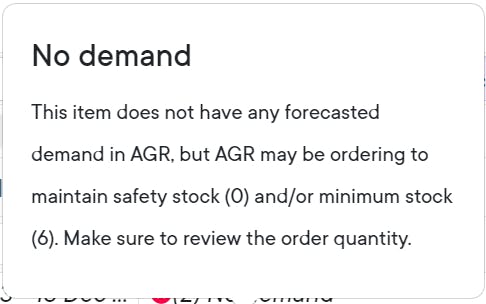

No Demand Indication

In cases where an item lacks demand in AGR, but safety stock considerations lead to order calculation, this exception nudges you to review the order quantity. You can adjust confidence factors to fine-tune your order strategy.

Precision at the Order Line Level

AGR's exceptional insights aren't limited to whole orders. Specific order lines are also flagged with exceptions, providing contextual explanations of why that flag occurs. Simply click on the flag name to open a box explaining the exception's relevance to that specific order line.

Dynamic Recalculations for Precise Decision-Making

Modifying orders is a dynamic process, and AGR understands that. When you alter an order's quantity or remove an order entirely, AGR springs into action. The system promptly recalculates the affected order lines, ensuring that you have the most accurate and up-to-date information at your fingertips.

Manage order exceptions seamlessly by incorporating AGR's Order Exception flags and Order Info sidebar into your order management process.

Our app is now live on Microsoft AppSource! Find it here.