AGR gives you smart forecasting, clear stock visibility, and fast time-to-value without the complexity of spreadsheets and legacy inventory systems. With over 400 customers globally, our inventory software is customisable to support your growth and supply chain processes.

With a quick integration, AGR takes all the sales data in your ERP and applies sophisticated statistical forecasting models to balance your warehouse and store inventory levels. This streamlines your stock, boosts productivity and facilitates high service levels.

Focus on your most profitable items and ensure they’re always in stock. You can remove the guesswork from your inventory management with highly accurate, automatic calculations. Strategically store safety stock to prevent the bullwhip effect.

AGR’s inventory optimisation software uses ABC analysis to automatically rank your products by value so you can focus your time, budget, and warehouse space on what matters most. By identifying top-performing items and aligning your safety stock accordingly, AGR helps you reduce excess inventory, prevent stockouts, and drive higher returns from every unit you hold.

AGR’s statistical forecasting engine uses your ERP data to deliver highly accurate automated forecasts. Make data-backed decisions and defend your inventory strategy with confidence at every meeting.

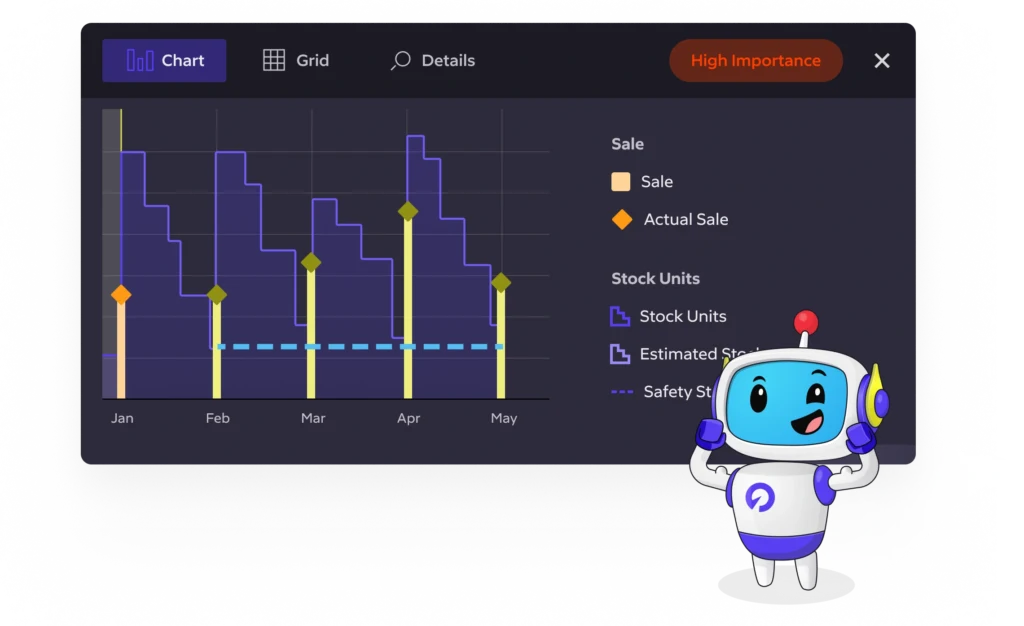

Graphical insights per item based on your product’s historic sales

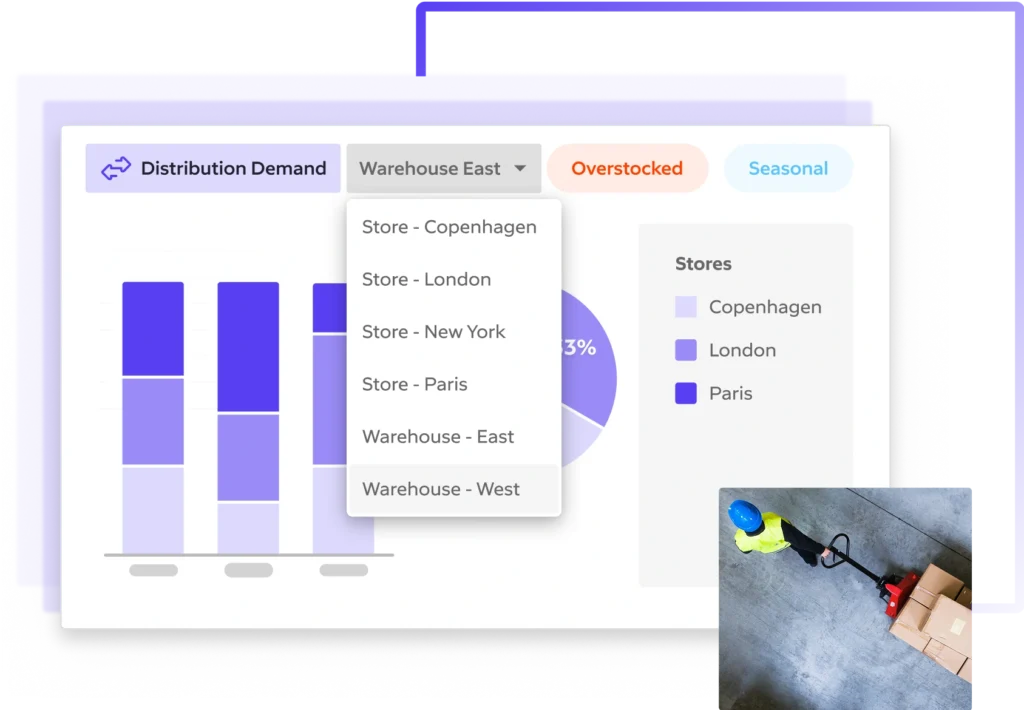

Forecasts for all locations including stores, warehouses, and channels

Automatic seasonality tags so you’re ordering seasonal products at the right time

Using the demand forecasts generated within AGR, you are then one click away from restocking inventory levels to meet customer demand and avoid excess inventory.

End-to-end automation of the entire replenishment process, from calculating reorder points and quantities to generating purchase orders sent to your ERP

Demand forecasting capabilities that anticipate future needs and adjust inventory accordingly to minimise both stockouts and overstocking

Minimised waste by reducing overstocking that creates write-offs or spoilage

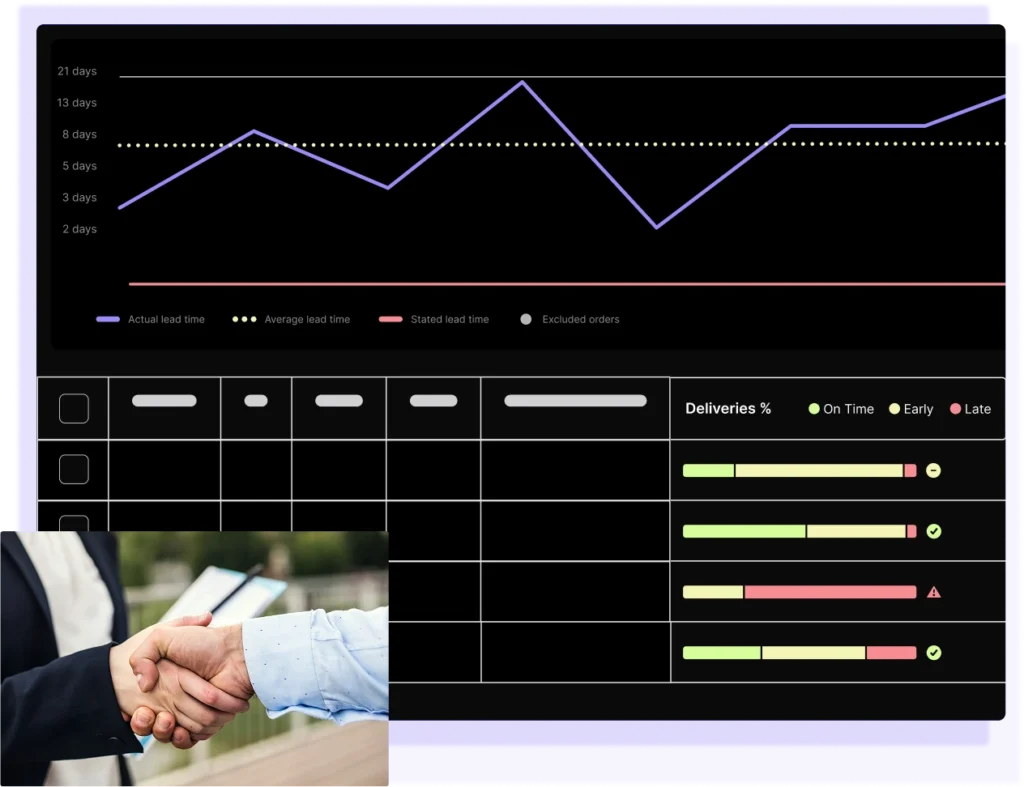

AGR gives you full visibility into supplier reliability, lead time trends, and fulfillment accuracy so you can make informed decisions, not reactive ones. With centralised vendor cards and live performance data, you can hold suppliers accountable, improve collaboration, and mitigate disruptions before they impact your bottom line.

AGR’s AI capabilities identifies trends, flags anomalies, and provides data-driven recommendations to guide supply chain teams. From demand anomalies to supplier risk, the system helps you see around corners and take proactive action.

Detect demand shifts and recommend forecast adjustments.

Get best-practice support from our AI Agent Finn, who gives you order recommendations

Learn from historical behavior to continuously improve recommendations.

Inventory that sits, costs. AGR helps you cut down on excess stock with smarter forecasting and automated replenishment so you’re holding just what you need.

Invest into your businesses growth.