Sales and Operations Planning (S&OP) is where business strategy meets supply chain execution. It aligns demand, supply, and financial planning so every department, from sales and marketing to operations and finance, works toward the same goals.

When done well, S&OP brings clarity, coordination, and confidence to decision-making. Instead of relying on fragmented data or siloed forecasts, companies create one integrated plan that balances customer demand with operational capability and business profitability.

Definition: What does S&OP mean?

S&OP stands for Sales and Operations Planning. It is a structured, cross-functional process that helps businesses synchronise demand forecasts with supply plans and financial objectives.

According to Oracle, S&OP transforms how businesses plan by connecting strategic goals to real-world execution. It acts as the “control tower” for your organisation’s planning landscape, linking sales performance, production capacity, and inventory levels.

Put simply, S&OP ensures that what your customers want, what your operations can produce, and what your finances can support all align within one consistent framework.

Why S&OP is essential for modern supply chains

Today’s supply chains operate in a landscape of constant disruption such as fluctuating demand, extended lead times, and shifting customer behaviour. Without S&OP, these pressures lead to reactive decision-making and poor visibility across teams.

An effective S&OP process helps you:

- Balance supply and demand to avoid shortages, stockouts, or excess inventory.

- Enhance collaboration between departments by providing a shared data foundation.

- Improve customer satisfaction by maintaining consistent service levels.

- Support profitability by aligning operational decisions with strategic business goals.

As SAP notes, S&OP acts as the bridge between operational detail and strategic intent, helping leaders make decisions that are not just feasible but financially sound.

The power of shared data in S&OP

S&OP is most effective when every team works from the same data and insights. When finance, operations, and sales each build plans from different systems, inconsistencies can quickly erode trust in forecasts and decisions.

A unified data foundation ensures that all stakeholders are viewing the same numbers, metrics, and reports. This creates alignment and removes debate over which figures are correct, allowing conversations to focus on action and outcomes instead of reconciliation.

As we explain in Less Waste, More Growth: The Case for Smarter Inventory and Supply Chain Data, having a single source of truth is essential for business growth. When inventory, sales, and supplier data are connected, teams can spot inefficiencies faster, reduce waste, and make proactive decisions that strengthen performance.

That visibility is the backbone of modern S&OP. It transforms data from static reporting into a dynamic, real-time driver of collaboration and profitability.

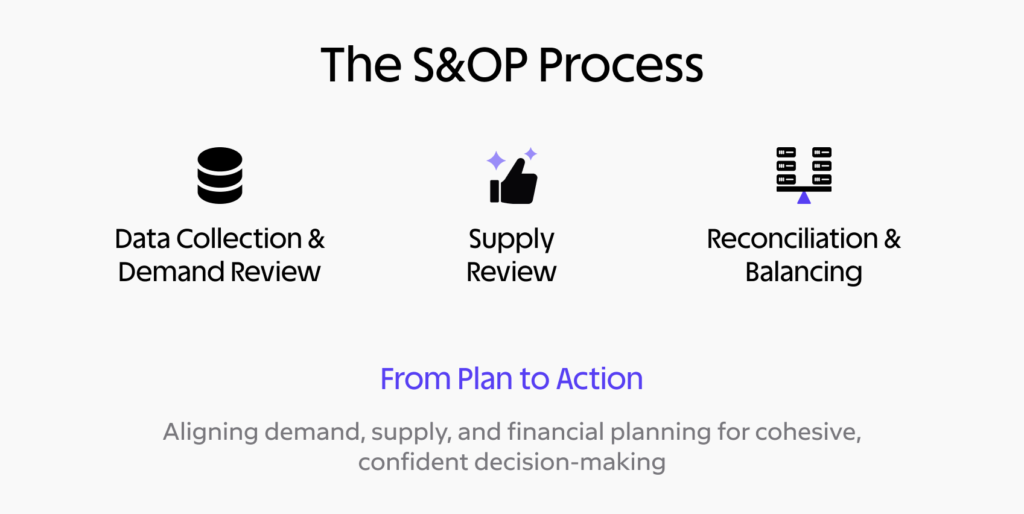

The S&OP process explained

The S&OP process typically runs on a monthly cycle, following a repeatable structure that keeps all teams aligned and accountable.

Step 1: Data collection and demand review

Start by consolidating sales data, forecasts, and market insights. This creates a single version of expected demand, often using advanced analytics and forecasting tools. The process allows teams to identify trends and assess how promotions, seasonality, or external events might affect demand.

Step 2: Supply review

Operations teams assess capacity, supplier performance, and production schedules. The aim is to understand whether current resources can meet forecasted demand and where bottlenecks might arise. This stage also examines alternative sourcing or production options to ensure flexibility and resilience.

Step 3: Reconciliation and balancing

This is where demand and supply meet. Cross-functional teams evaluate trade-offs, test scenarios, and agree on the most viable plan that satisfies both operational and financial constraints. It is often the most collaborative stage, where strategic alignment and data transparency are critical to reaching consensus.

Step 4: Executive review and decision-making

The final stage turns the plan into action. Senior management reviews the integrated plan, resolves conflicts, and signs off on the strategy. By aligning decisions at the executive level, the business ensures every function is working from one cohesive, financially sound plan.

By repeating this process regularly, businesses maintain agility and can adjust quickly when market conditions or customer behaviour shift.

Key benefits of effective S&OP

When the S&OP process is mature, its impact extends across the entire organisation.

Improved forecast accuracy

Integrating sales, operations, and finance reduces guesswork. Forecasts become grounded in data, leading to more reliable demand signals and fewer surprises.

Reduced stockouts and excess inventory

With a balanced plan, inventory levels stay lean but sufficient. This improves cash flow while keeping customers happy and shelves full.

Better collaboration and visibility

S&OP builds a shared understanding of priorities across departments, supported by transparent data. Teams stop operating in silos and start working from one unified plan.

Enhanced profitability and agility

Real-time scenario analysis helps teams see the financial impact of decisions before acting. The result is faster responses, more confident planning, and improved margins.

Common challenges in Sales and Operations Planning

S&OP can deliver major improvements, but only when supported by reliable data and strong collaboration. Some of the most common challenges include:

- Data inconsistency between systems, making it difficult to build a single view.

- Conflicting KPIs that drive competing priorities across teams.

- Limited executive engagement, slowing decision-making.

- Manual processes that make plans outdated as soon as they are produced.

Overcoming these barriers requires technology that unites data, automates updates, and supports real-time decision-making so teams can focus on strategy, not spreadsheets.

How S&OP integrates with forecasting, ERP, and analytics

Inventory optimisation software does not replace your existing tools; it enhances them. Enterprise Resource Planning (ERP) systems remain the backbone of operational data, but stock management platforms extend that data into future-focused planning.

Our inventory optimisation software builds on ERP data by combining real-time demand forecasting, inventory visibility, and financial insights in one platform. This creates a living plan that updates automatically as market conditions change.

For example:

- Forecast accuracy improves through advanced modelling and AI-driven adjustments.

- Cross-functional teams gain a shared view of inventory, demand, and supply capacity.

- Decision-makers can simulate “what-if” scenarios before acting.

This kind of integration transforms S&OP from a static reporting exercise into a dynamic decision engine.

The role of AI and automation in S&OP

Artificial intelligence and machine learning are reshaping how S&OP works. Instead of manually adjusting forecasts, AI models analyse historical data, external factors, and real-time inputs to predict demand more precisely.

This is especially powerful when combined with AGR’s automation features, which monitor key inventory and KPI metrics continuously. By surfacing insights on stock levels, supplier reliability, and turnover ratios, businesses can make proactive adjustments rather than reacting to problems.

AI also supports scenario planning by helping leaders understand how changes in pricing, lead time, or supply constraints could affect both service levels and profit margins.

How AGR enhances the S&OP process

AGR strengthens every stage of S&OP by giving companies the visibility and control they need to make decisions confidently.

- Integrated data sources: Combine ERP, sales, and supply chain data into one environment.

- Real-time insights: Track changes in demand, inventory, or lead times instantly.

- Scenario analysis: Model different outcomes to test business decisions before implementing them.

- Actionable automation: Trigger replenishment or forecast updates automatically based on real data.

The result is an S&OP process that is faster, smarter, and more responsive. With AGR, teams no longer rely on retrospective reports; they work with live, predictive insight that drives better results.

FAQs about S&OP

What does S&OP stand for?

S&OP stands for Sales and Operations Planning, a cross-functional process that aligns supply, demand, and financial goals.

What is the main goal of S&OP?

The main goal is to create a single, data-driven plan that balances operational capability with market demand and business strategy.

What’s the difference between S&OP and demand planning?

Demand planning focuses on predicting future demand, while S&OP integrates that forecast into a wider operational and financial plan.

How does S&OP improve supply chain performance?

S&OP improves supply chain performance by ensuring all departments work from the same plan and dataset. When everyone looks at the same metrics and reports, teams can act faster and with more confidence. This alignment reduces inefficiencies, enhances visibility across the organisation, and enables informed, strategic action.