In today’s inventory-heavy industries—whether you’re in retail, manufacturing, or wholesale—knowing where your stock is and what it’s doing isn’t just helpful, it’s business-critical. And the key to unlocking that visibility? SKUs.

This article explains what a SKU (Stock Keeping Unit) is, how it’s used in inventory management, and why mastering SKU logic is a practical step towards smarter, more profitable planning.

SKU explained: The basics

To make the most of your inventory, you need to start with a clear definition. In this section, we unpack what a SKU really is, how it differs from a UPC, and why it matters in your supply chain.

What does SKU stand for?

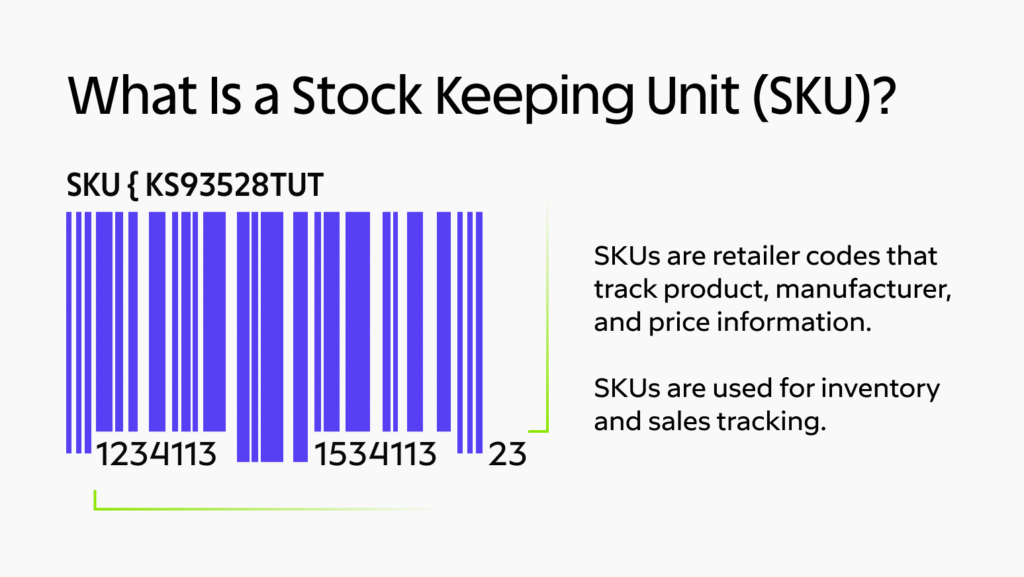

SKU stands for Stock Keeping Unit—a unique identifier for each product or item in your inventory. A SKU is usually alphanumeric and built around logical categories such as product type, size, colour, or model. It’s not randomly assigned; it’s designed with meaning to streamline operations.

For example, a retailer selling a black, size 10 trainer might assign it the SKU: SH-BL-10. Every other variation—say, the white version or a size 9—gets its own SKU.

In a wholesale scenario, a distributor selling cases of canned soup might use SKUs like SOUP-TOM-24 for a 24-pack of tomato soup and SOUP-CHK-24 for chicken soup, helping them manage pallets, pricing tiers, and replenishment more precisely.

You create and define SKUs internally to suit your own operations. That means you have full control over the structure, unlike UPCs (Universal Product Codes), which we’ll cover next.

How SKUs differ from UPC

While a UPC is a globally standardised barcode regulated by GS1 and used for scanning at tills, a SKU is created by you and tailored to your internal processes. Think of the UPC as the passport and the SKU as the internal HR record.

| Feature | SKU | UPC | |||

| Customisable | Yes | No | |||

| Internal use | Yes | No | |||

| Global standard | No | Yes |

SKUs help you make decisions internally. UPCs help you sell externally.

Why SKUs are critical for modern supply chain management

SKUs provide the foundation for many of the systems businesses use to manage inventory efficiently. They drive decisions in forecasting, replenishment, warehousing, and profitability.

A well-structured SKU system helps you:

- See what’s in stock and where it is

- Track sales trends

- Identify slow-moving products

- Avoid over-ordering

- Reduce deadstock

Without structured SKU logic, businesses often struggle with inventory blind spots—leading to costly stockouts or waste.

Key applications of SKUs in supply chain and inventory

SKUs aren’t just for counting what you’ve got—they’re the linchpin for everything from tracking movement to predicting future needs. This section looks at how SKU data feeds the core operational functions that keep your supply chain agile and efficient.

Inventory tracking and control

Every time a product moves—whether it’s delivered, sold, returned or written off—the SKU acts as the tracking reference. This helps your team understand what’s on hand, what’s committed to customer orders, and what needs replenishing.

Advanced inventory systems like AGR use SKU data to automate reorder suggestions and flag anomalies such as sudden drops in availability.

Forecasting and demand planning accuracy

Your demand planning system can only forecast what it understands. SKUs ensure every data point is tied to a specific product.

When you tag sales, returns and usage to distinct SKUs, your system can accurately spot patterns and generate more reliable forecasts. Want to learn more about that link? Read our full guide on demand forecasting best practices.

Return handling and reverse logistics

Returns management is far smoother when every product has a clear identifier. SKUs help you:

- Verify returns against original orders

- Assess return frequency by SKU

- Flag SKUs with unusually high return rates

This data is essential for improving product quality and refining your assortment.

How SKUs shape warehouse efficiency

Warehouse operations live or die by efficiency—and SKU data is central to making that happen. In this section, we explore how smart SKU design can streamline your layout, picking process, and overall warehouse flow.

Optimising with SKU data

In the warehouse, time is money. The faster your team can find, pick and ship products, the better your margins.

Organising warehouse layout based on SKU movement patterns—known as ABC classification—is a smart strategy. Place fast-moving SKUs in easily accessible zones, while slower-moving or seasonal items can live further away.

You can also use SKU data to inform:

- Slotting optimisation

- Batch picking routes

- Automated storage and retrieval

The outcome? Lower pick times, higher accuracy, and less overtime.

Best practices for SKU management

Managing SKUs well isn’t just about neat codes—it’s about making smarter decisions across your supply chain. Here, we’ll cover how to build a scalable system that integrates seamlessly with your planning tools and drives long-term efficiency.

Integrating SKU logic with your demand planning tools

SKU data should never live in isolation. To get the most out of it, integration with your demand planning system is essential. This ensures every inventory decision—from reordering to phase-out—is based on up-to-date, SKU-specific insights.

Seamless integration helps unify sales history, supplier lead times, and product hierarchies across departments. That means your planners, warehouse team, and procurement staff are all working from the same data source. It reduces manual errors, prevents duplication, and enables more accurate forecasting.

The goal isn’t just to store data—it’s to activate it. When your SKU logic connects directly with your planning tools, you can automate replenishment, monitor trends in real-time, and simulate different demand scenarios. Whether you’re managing thousands of SKUs or a high-value, curated assortment, this kind of integration turns your inventory from a static list into a strategic asset.

The role of AI in SKU and inventory optimisation

Artificial intelligence is no longer just a buzzword in inventory circles—it’s an operational advantage. As we shared in our deep dive on AI in inventory management, the technology helps planners cut through complexity, especially in fast-moving or high-SKU environments. By automatically analysing historical sales, supplier lead times, and demand volatility, AI tools reduce the guesswork. You spend less time on manual forecasts and more time making proactive decisions—like which SKUs to prioritise for replenishment or markdown. It’s not about replacing human planners; it’s about giving them superpowers.

Using AI to detect product trends by SKU

AI-powered inventory tools can analyse SKU-level data to uncover patterns no human planner could detect. For example:

- Identifying demand surges linked to seasonal promotions

- Spotting underperforming SKUs at risk of deadstock

- Flagging emerging bestsellers before the competition

AGR’s forecasting engine uses AI and machine learning to segment products and fine-tune forecasts automatically based on SKU history. This is especially powerful for complex assortments or high-SKU environments.

Want to see how it works in the real world? Read our Ole Lynggaard case study where we helped streamline inventory and boost availability. As a luxury jewellery brand with a relatively small but high-value assortment, Ole Lynggaard needed precise control over each SKU. Managing a limited number of SKUs didn’t make visibility less important—in fact, it made accuracy more critical. AGR’s AI-driven forecasting allowed the team to align replenishment to actual demand, protect margins, and maintain premium service levels without overstocking costly inventory.com/studies/ole-lynggaard/) where we helped streamline inventory and boost availability. As a luxury jewellery brand with a wide assortment and seasonal product cycles, Ole Lynggaard needed tighter SKU visibility to improve planning accuracy. AGR’s AI-driven forecasting allowed the team to align replenishment to actual demand, reduce overstock, and maintain high service levels without tying up excess capital in inventory.

FAQs about SKUs

Is a SKU unique to each company?

Yes. SKUs are company-specific. The same product could have completely different SKUs at two retailers. That’s why it’s essential to design a system that fits your own product hierarchy, reporting, and logistics.

How do I build a SKU system from scratch?

Start simple. A good SKU structure reflects your key product categories. Here’s a basic framework:

- [Category]-[Colour]-[Size]

- SH-BL-10 = Shoe, Black, Size 10

Some companies also include year or season codes to help manage product lifecycles. Consistency is key. And make sure to document your logic for future team members.

In wholesale, especially in industries like auto parts or electrical components, SKUs often encode technical specifications that are critical for compatibility and compliance. For example:

- RELAY-24V-5A-NO = Relay, 24 volts, 5 amps, normally open

- CBL-HVY-3M = Heavy-duty cable, 3 metres

- FUSE-10A-FAST = 10-amp fast-blow fuse

This level of precision helps prevent errors in fulfilment and ensures that customers get exactly what they need—especially when products are similar in appearance but different in function.

Should I use AI to manage my SKU database?

If you’re managing more than a few hundred SKUs, yes—absolutely. AI helps:

- Flag duplicates and inconsistencies

- Predict demand at SKU level

- Automate replenishment

Combined with demand planning tools, AI can take your SKU logic from reactive to proactive.