Global supply chains are under constant pressure ranging from unpredictable demand to rising logistics costs. To stay competitive, businesses need smarter tools that improve inventory optimisation, enhance visibility, and reduce manual effort in supply chain planning. AGR’s latest releases delivers exactly that, with powerful upgrades designed to give planners more control, speed, and flexibility.

Smarter reporting with server side grids and advanced filters

We are rolling out a new server side grids across reports and item views, designed to handle larger datasets and deliver insights faster. This upgrade ensures AGR can support growing businesses with more supply chain complexity.

Alongside it comes Advanced Filters 2.0, giving planners greater flexibility to build custom reports including the ability to filter by safety stock and custom columns. These enhancements make it easier to identify risk, optimise your stock levels, and act quickly on supply chain surprises.

More control in inventory constraints and order planning

To help businesses better balance stock availability with working capital, AGR now supports:

- Custom constraint columns: Configure numeric fields such as vendor lead times or cost factors as constraints in the planning process.

- Configurable order multiple thresholds: Adjust ordering logic to match business needs, directly from your Settings.

- Conditional order logic at SKU level: Fine-tune replenishment rules item by item, ensuring smarter allocation of resources.

These features allow businesses to model constraints more accurately and align replenishment strategies with real-world supply chain challenges.

Streamlined automated orders

Inventory managers can now automate more complex ordering scenarios with new Scheduled Order enhancements:

- Split orders by columns such as item groups or custom fields

- Combine multiple locations into one schedule for efficiency

- Apply exclude filters for greater control over vendor and store ordering rules

This flexibility reduces the need for your manual intervention, making it easier to set up your initial order rules and maintain optimal stock levels across networks of warehouses and stores.

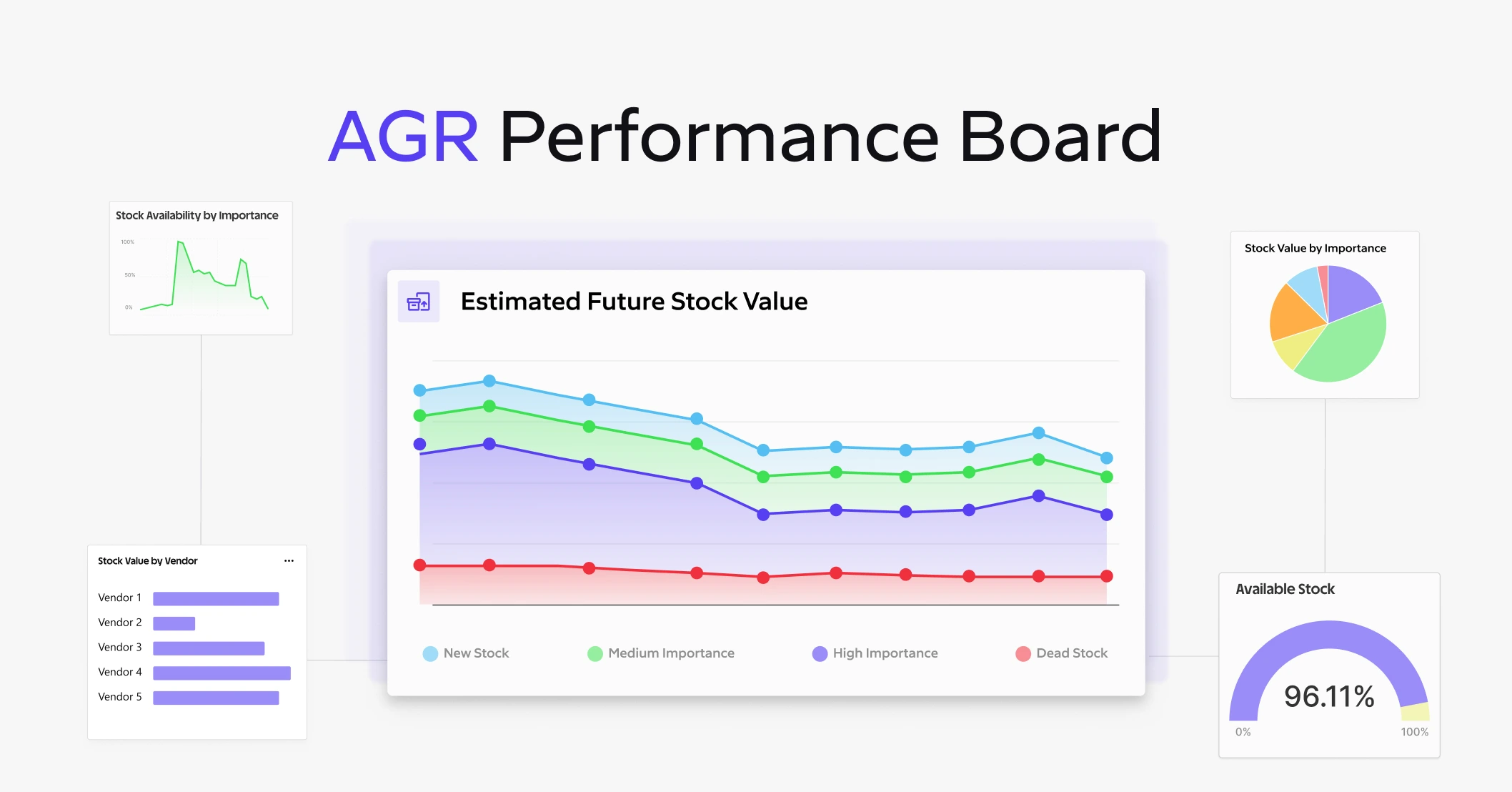

Enhanced insights and performance

To support more accurate demand and supply decisions:

- Split orders by various constraints has been optimised and now performs over 100x faster than legacy systems.

- Total sales charts provide a clearer view of demand trends by location.

- Location type classification (Warehouse vs. Store) enables future reporting and policy differences for stock optimisation.

- System performance improvements cut daily stockout refresh times by up to 40 minutes.

Why this matters now

From shipping delays to inflationary pressures, businesses are being forced to rethink how they manage inventory. This release is designed to help companies:

- Optimise inventory levels across multiple locations

- Improve demand visibility and reporting accuracy

- Automate complex ordering logic to save time and reduce errors

- Build resilience into their supply chain planning

With these enhancements, AGR continues to strengthen its position as a leading platform for inventory optimisation and S&OP planning, helping businesses stay ahead in an unpredictable supply chain landscape.