AI inventory optimisation has moved from a promising concept to a practical capability that many supply chain teams now rely on. What once required complex models, spreadsheets, and manual judgement can now be handled dynamically, using artificial intelligence to connect forecasting, planning, and execution.

This article explains what AI inventory optimisation looks like today, how it works in practice, and why it represents a clear shift from how inventory decisions were made even a few years ago.

What is AI inventory optimisation?

AI inventory optimisation is the use of artificial intelligence and machine learning to continuously improve how inventory is planned, positioned, and replenished across the supply chain. It brings together demand forecasting, inventory policies, and optimisation logic into a single, adaptive system.

Instead of relying on fixed rules or periodic reviews, AI-driven optimisation responds to change as it happens. Demand signals, supplier performance, and stock movements are analysed continuously, allowing inventory decisions to evolve alongside the business.

At its core, AI inventory optimisation aims to balance three competing priorities: availability, cost, and risk. The difference is that this balance is recalculated constantly, rather than reviewed after problems occur.

Why traditional inventory approaches fall short

Traditional inventory management assumes a level of stability that rarely exists in modern supply chains. Demand is averaged, lead times are treated as fixed, and safety stock is adjusted infrequently. When conditions change, teams react after the impact is already visible.

This approach becomes increasingly fragile as complexity grows. More SKUs, more locations, shorter lifecycles, and volatile demand patterns all increase the risk of stockouts, excess inventory, or both at the same time.

AI inventory optimisation takes a different approach. Rather than asking planners to predict every scenario, it uses data and learning models to adapt decisions automatically. This shifts inventory management from reactive correction to continuous optimisation.

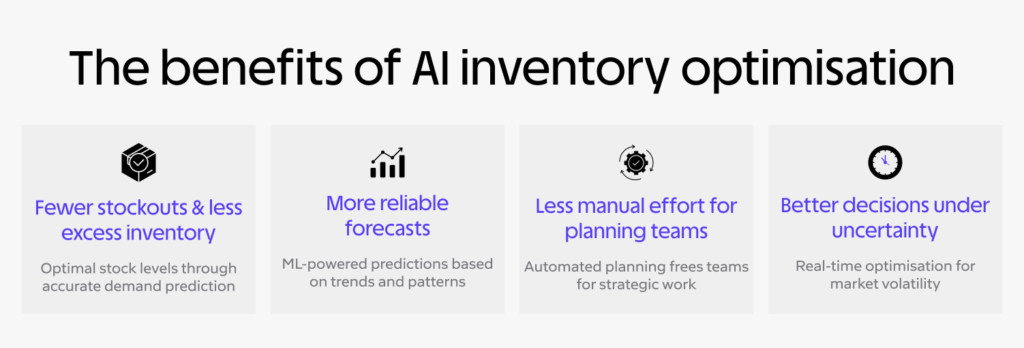

The benefits of AI inventory optimisation

While the technology behind AI inventory optimisation is sophisticated, the outcomes are straightforward. Businesses tend to see improvements in a few key areas.

Fewer stockouts and less excess inventory

AI continuously adjusts reorder points, safety stock, and order quantities based on real demand and supply behaviour. This reduces the risk of running out of stock without inflating inventory buffers unnecessarily.

More reliable forecasts

Machine learning models identify patterns that traditional methods often miss. Seasonality, trend changes, and demand volatility are handled more effectively, leading to forecasts that improve over time rather than degrade.

Less manual effort for planning teams

By automating routine calculations and adjustments, AI reduces the need for spreadsheet-driven planning. Teams can focus on exceptions, supplier collaboration, and strategic decisions instead of constant rework.

Better decisions under uncertainty

AI does not assume certainty. It accounts for variability in demand and supply, helping businesses understand trade-offs between service levels, cost, and risk rather than relying on single-point estimates.

How AI inventory optimisation works in practice

AI inventory optimisation is not a single model or feature. It is a connected set of capabilities that support better decisions across the inventory lifecycle.

Demand forecasting with machine learning

AI-driven forecasting models learn from historical demand, sales patterns, and behavioural signals. Forecasts are updated continuously as new data becomes available, allowing them to reflect current conditions rather than last quarter’s assumptions.

This builds on ideas explored earlier in AI: A game changer in supply chain demand forecasting, where the focus was on improving prediction accuracy. What has changed since then is how closely forecasting is now linked to execution.

Inventory optimisation models

Forecasts alone do not prevent stock issues. AI inventory optimisation extends forecasting into decision-making by calculating optimal inventory levels based on business priorities.

These models consider factors such as service level targets, lead time variability, supplier reliability, and cost trade-offs. The goal is not to minimise inventory, but to hold the right inventory in the right places.

Continuous monitoring and automated replenishment

AI systems monitor inventory positions and demand signals in real time. When conditions change, replenishment parameters are recalculated automatically. Orders are triggered based on current risk and demand, not static thresholds.

This creates a planning environment that adapts continuously rather than relying on fixed review cycles.

What has changed since we last wrote about AI in forecasting

When we previously explored AI in the context of demand forecasting, the emphasis was on prediction. At the time, the main breakthrough was that AI could forecast demand more accurately than traditional statistical methods.

Since then, the role of AI has expanded.

Forecasting is no longer an isolated activity. Today, forecasts feed directly into inventory optimisation models that determine safety stock, reorder points, and replenishment decisions. The manual step where planners translate forecasts into rules has largely disappeared.

This shift is important. Better forecasts only create value when they influence day-to-day decisions. AI inventory optimisation reflects this evolution by closing the gap between insight and action.

From optimisation models to everyday decision support

Another change is how accessible AI has become for inventory and supply chain teams.

Not long ago, AI worked quietly in the background. While recommendations improved, understanding why a decision was made often required reports, dashboards, or specialist support. This created distance between AI outputs and the people responsible for acting on them.

That gap is now narrowing.

With tools like Finn, AGR’s AI-powered assistant, AI is no longer just calculating outcomes. It is explaining them. As described in AGR’s news update on how Finn gives fast, accurate answers, users can ask direct questions about inventory, demand, or risk and receive immediate, data-backed responses.

This matters for inventory optimisation. AI-driven recommendations only deliver value when teams trust them and can act quickly. By making AI conversational and transparent, inventory optimisation becomes something planners actively engage with rather than something that happens out of sight.

The result is a more responsive planning environment. Inventory decisions are not only optimised by AI, but also understood, challenged, and refined by the people closest to the operation.

Where AI inventory optimisation is most effective

AI inventory optimisation can be applied across all major inventory types, adapting to different planning challenges and operational realities.

- Raw materials and components

AI helps balance supplier lead times, minimum order quantities, and demand variability, reducing the risk of production delays without tying up unnecessary capital. - Work-in-progress inventory

By monitoring production flow and demand signals, AI supports smoother throughput and prevents bottlenecks or excess build-up between stages. - Finished goods

AI improves availability at the customer-facing end of the supply chain by aligning stock levels with real demand patterns, seasonality, and service level targets. - Spare parts and maintenance stock

AI is particularly effective where demand is irregular and critical, helping ensure availability for maintenance and repairs without overstocking slow-moving items.

While each category has different demand patterns and risk profiles, the underlying optimisation principles remain the same. AI adapts the models to fit the context rather than forcing one-size-fits-all rules.

Common challenges and how to address them

AI inventory optimisation is powerful, but it is not automatic success. A few practical considerations matter.

Data quality and integration

AI depends on reliable data. Clean master data, consistent transactions, and well-integrated systems are essential. Without them, even the most advanced models will struggle.

Balancing automation and human judgement

AI should support planners, not replace them. The strongest results come from combining automated recommendations with human oversight, especially when managing exceptions or strategic trade-offs.

Scaling with transparency

As inventory networks grow more complex, explainability becomes critical. Teams need to understand how and why decisions are made to maintain trust and alignment with business goals.

What comes next for AI inventory optimisation

AI inventory optimisation continues to evolve.

Integration with ERP systems and real-time data sources is deepening. Predictive analytics is increasingly complemented by prescriptive recommendations that explain not just what might happen, but what action to take.

Perhaps most importantly, AI systems are learning continuously. As markets, suppliers, and customer behaviour change, inventory strategies can adapt without constant redesign.

Frequently asked questions about AI inventory optimisation

What is AI inventory management?

AI inventory management uses artificial intelligence to forecast demand, optimise inventory levels, and automate replenishment decisions based on continuous data analysis.

What does AI optimisation mean?

AI optimisation refers to using algorithms to evaluate multiple scenarios and select the best outcome based on defined objectives, constraints, and risk.

How does AI improve stock management?

AI improves stock management by increasing forecast accuracy, adapting to change, and reducing the need for manual intervention in routine decisions.

What are the four types of inventory management?

The four common types are raw materials, work-in-progress, finished goods, and maintenance or spare parts inventory.

What are the main challenges of AI inventory management?

The main challenges are data quality, system integration, transparency, and maintaining the right balance between automation and human control.