Inventory planning is the process of determining the ideal quantity and timing of stock to meet customer demand efficiently. It allows businesses to anticipate sales patterns and respond before issues arise. A clear planning approach helps teams make better decisions and avoid reactive, costly stock corrections.

Inventory planning is essential for balancing supply, demand, and cash flow in a fast-moving business environment. It ensures that stock levels support customer needs without creating excess inventory or operational waste. By using accurate data, structured processes, and the right tools, companies can plan confidently, reduce risk, and build a resilient supply chain.

The goal of inventory planning

The goal of inventory planning is to strike the right balance between availability and cost. Businesses aim to maintain strong service levels while avoiding the capital drain of holding too much inventory. A well-designed planning framework enables companies to scale with confidence and maintain operational stability.

The role of data in modern inventory planning

Data plays a central role in accurate planning because it reveals how products behave over time. Businesses depend on clean sales, stock, and supplier data to build reliable forecasts and replenishment rules. With accurate information, organisations gain the clarity they need to make decisions at speed and adapt to changing market conditions.

Why inventory planning is important

Effective planning enables businesses to improve profitability, reduce risk, and operate more efficiently. Without a consistent approach, stock levels become unpredictable, leading to shortages, surplus stock, and cash flow pressure. Strong planning gives companies the stability they need to grow sustainably and protect customer relationships.

Improve cash flow and profitability

Better planning helps businesses avoid overstocking and reduce working capital tied up in inventory. This frees funds for growth activities and protects margins against unexpected demand fluctuations. Strong cash flow also makes businesses more resilient to market changes and supplier disruption.

Reduce waste and overstocking

Good planning prevents excess stock, which reduces write offs, holding costs, and waste. It also minimises the operational burden of storing and managing unnecessary inventory. Lower waste improves overall efficiency and environmental performance, helping businesses meet sustainability goals.

Enhance customer satisfaction

Meeting demand consistently helps businesses deliver a reliable customer experience. When products are available at the right time, customers feel confident in the brand and purchase more often. This reliability strengthens long term relationships and supports repeat business.

Strengthen supplier relationships

Forecast clarity and predictable order patterns support stronger collaboration with suppliers. When suppliers have better visibility, lead times become more stable and service levels improve. This reliability reduces disruptions and supports smoother planning cycles across the supply chain.

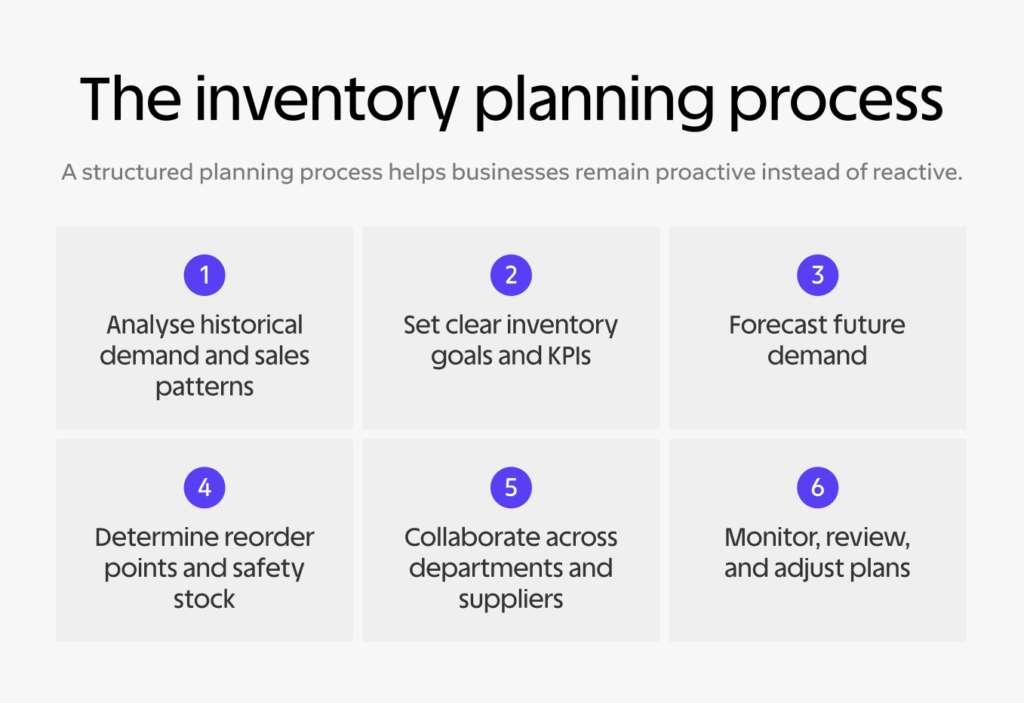

The inventory planning process

A structured planning process helps businesses remain proactive instead of reactive. Each stage builds on the previous one, creating a clear path towards consistent and accurate inventory decisions. Strong processes also help teams work together more effectively and remain aligned on priorities.

1. Analyse historical demand and sales patterns

Analysing historical demand helps identify seasonal patterns, growth trends, and anomalies that influence future sales. This insight supports more accurate forecasting and reduces guesswork. Better visibility of past behaviour helps prevent repeated planning errors and unnecessary stock build up.

2. Set clear inventory goals and KPIs

Setting goals and KPIs provides direction and ensures plans support business objectives. Metrics such as service levels and stock turns create measurable targets for improvement. Clear KPIs enable faster decision making and more focused planning for all departments.

3. Forecast future demand

Forecasting gives businesses a forward-looking view of expected sales and helps them plan accordingly. When teams combine statistical methods with commercial insight, accuracy improves significantly. Forecasts also provide early warnings about shifts in demand and help avoid stock imbalances. Read more in our guide on demand forecasting.

4. Determine reorder points and safety stock

Reorder points and safety stock protect the business from variability in supply and demand. They provide a buffer that maintains service levels even when conditions change. Strong replenishment rules prevent both shortages and excessive stock, allowing operations to stay dependable.

5. Collaborate across departments and suppliers

Cross functional collaboration ensures planning is aligned with promotions, purchasing cycles, and production schedules. It helps avoid surprises and keeps the business operating smoothly. Effective collaboration also strengthens accountability across teams and reduces operational friction.

6. Monitor, review, and adjust plans

Inventory plans must be reviewed and updated frequently to reflect real conditions. Continuous monitoring helps businesses respond quickly to market changes and supplier constraints. A rhythm of regular updates keeps plans relevant and prevents costly planning mistakes.

Inventory planning methods and models

Different methods support different types of stock, demand patterns, and operational constraints. Choosing the right model helps businesses create a planning approach that fits their unique environment. Many organisations combine methods to improve accuracy and planning flexibility.

Demand driven planning

Demand driven planning uses accurate forecasting and market insight to guide replenishment. This method is effective when demand patterns are relatively predictable and data quality is high. It helps businesses respond quickly to changes in customer behaviour and maintain steady availability.

Economic order quantity (EOQ)

Economic order quantity helps determine the most cost-efficient order size that balances purchasing and holding costs. This model works well for stable products where demand and lead times are consistent. It reduces unnecessary expenses and supports efficient buying habits across product groups.

Minimum order quantity (MOQ)

Minimum order quantity planning recognises supplier constraints and accounts for required order thresholds. Understanding MOQs helps planners avoid over ordering or accumulating excess stock. It also helps strengthen supplier negotiations and improve overall purchasing discipline. Learn more in our guide on MOQ meaning.

FIFO and stock rotation

FIFO keeps stock fresh by ensuring the oldest inventory is used or sold first. It reduces waste, prevents write offs, and improves product quality. Strong rotation is particularly important for perishables and high value items where quality deteriorates over time. Read more about these principles in our guide on FIFO meaning.

ABC and XYZ combined models

ABC classification prioritises planning effort based on item importance, while XYZ classification adds demand variability into the mix. Together, they help businesses understand which items require strict control and which need flexible strategies. This combination supports targeted, efficient planning and smarter stock investment. Learn more in our guide to ABC analysis.

Inventory planning examples

Real life planning scenarios make it easier to understand how different industries apply forecasting, safety stock, and replenishment rules. These examples show how planning decisions adapt depending on demand patterns, lead times, and product characteristics.

Example 1: Industrial cleaning supplies wholesaler

An industrial cleaning supplies wholesaler stocks items such as disinfectants, paper goods, gloves, and floor cleaning chemicals, all with relatively stable but seasonal demand patterns. Their historical data shows predictable spikes during winter and during large contract renewals, so planners increase safety stock around these peak periods. Lead times from chemical suppliers remain consistent, which enables the business to rely on statistical forecasting models and automated replenishment proposals. By reviewing usage patterns across major customers, they reduce excess stock of slow-moving lines and maintain strong service levels for essential items.

Example 2: Electronics components wholesaler

An electronics components wholesaler carries fast moving items such as resistors, sensors, and connectors, alongside slower special-order components with volatile demand. Since many items have long international lead times and are subject to rapid technological change, planners combine forecasting with ABC classification to prioritise investment in the most critical components. They determine which components require higher safety stock due to long lead times and which should be ordered in smaller batches to avoid obsolescence. Using exception alerts and ageing stock reports, they respond quickly to demand changes and prevent expensive write offs of outdated parts.

Best practices for smarter inventory planning

Good planning relies on discipline, data quality, and consistent process execution. These best practices help build a strong planning foundation and improve performance over time. Businesses that follow them gain greater confidence and operational clarity across their supply chain.

Leverage accurate data and analytics

Accurate data reduces errors and leads to more reliable stock decisions. It enables better forecasting, cleaner reporting, and stronger performance visibility. Improved data quality also supports automation and more proactive exception management.

Integrate forecasting with ERP systems

Integrating systems ensures information flows smoothly across purchasing, warehousing, and planning teams. It reduces mismatches between forecasts and actual stock levels. Strong integration improves response times during peak demand periods and supports scalable growth.

Track key inventory KPIs

Monitoring KPIs highlights opportunities for improvement and prevents problems from escalating. Important KPIs include service level, stock turns, forecast accuracy, and working capital usage. Consistent tracking creates accountability and supports a culture of continuous improvement.

Continuously refine your planning models

Markets change and demand patterns evolve, so planning models must adapt. Regular reviews help businesses stay ahead of shifts in behaviour and supply constraints. A cycle of improvement strengthens resilience and supports long term operational performance.

How AGR supports smarter inventory planning

AGR provides advanced forecasting, replenishment, and analytics tools that help wholesalers and distributors plan with confidence. Each feature is designed to simplify processes and improve decision making. With AGR, businesses gain the clarity they need to act quickly and accurately.

Demand planning and forecasting

AGR’s demand planning and forecasting module uses statistical models and machine learning to predict future demand. It identifies patterns, trends, and exceptions so planners can adjust quickly. This leads to more stable service levels and smarter stock investment decisions that support profitability.

Automated replenishment

AGR’s automated ordering module calculates optimal reorder points and produces purchase proposals that balance availability and cost. It reduces manual work and helps teams avoid stockouts and excess stock. Automated replenishment also improves purchasing consistency and reduces human error.

Real time reporting and performance insight

The Insights and reports module gives planners a clear view of inventory performance, risk areas, and opportunities for improvement. Combined with the performance board, it enables faster decision making at every level. These tools help teams stay in control of complex stock portfolios and focus on high impact tasks.

Smarter stock rotation and exception management

AGR highlights ageing stock, potential deadstock, and replenishment exceptions before they become costly issues. This proactive approach keeps stock healthy and prevents avoidable waste. Better visibility enables businesses to act early and maintain a strong planning rhythm.

FAQs about inventory planning

What is the difference between inventory planning and inventory management?

Inventory planning focuses on future stock needs, while inventory management deals with stock that already exists. Planning creates the strategy and management executes it. Both are essential for a smooth and efficient supply chain.

How often should inventory plans be updated?

Most businesses review their plans monthly, although volatile sectors may update them more frequently. Regular updates keep plans aligned with current conditions. This rhythm helps teams remain proactive and accurate.

What KPIs should I track in inventory planning?

Important KPIs include service level, stock turns, forecast accuracy, and excess stock levels. These metrics help measure efficiency and highlight areas for improvement. Tracking them regularly strengthens planning discipline.

Which software is best for inventory planning?

The best software includes accurate forecasting, automated replenishment, and clear reporting. AGR Inventory is designed specifically for wholesalers and distributors who need reliable, data driven planning. Its tools help businesses reduce waste and improve performance across all inventory processes.

Improve your inventory planning with AGR Inventory

AGR Inventory helps businesses plan smarter, improve cash flow, and reduce waste with advanced forecasting and replenishment tools. Book a demo to see how AGR can transform your planning and support sustainable, profitable growth.