OTIF, short for On Time in Full, is one of the most important performance metrics in modern supply chains. It measures whether customers receive the right products, in the right quantities, at the promised time. When OTIF is high, customer trust improves and operations run more smoothly. When it drops, the consequences are often felt across sales, inventory, and supplier relationships.

This guide explains the OTIF meaning, how it is calculated, why it matters, and what businesses can do to improve OTIF performance in practice.

What is OTIF?

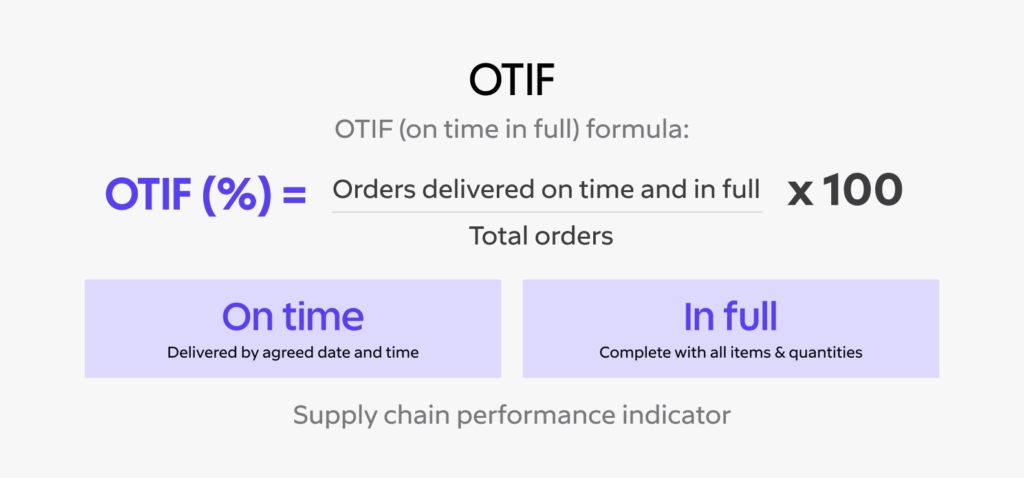

OTIF is a key supply chain performance KPI that tracks whether deliveries meet two conditions at the same time: arriving on time and being delivered in full. This makes OTIF a stricter and more demanding metric than many other service-level measures, as partial success does not count as a pass.

For an order to be OTIF compliant, it must meet both criteria. If a shipment arrives on time but is missing items, it fails OTIF. The same applies if the order is complete but late.

OTIF in a supply chain context

In supply chain management, OTIF is used to measure reliability across planning, warehousing, and distribution. It reflects how well demand forecasting, inventory availability, picking accuracy, and transport execution work together. Decisions made upstream in planning and procurement therefore have just as much influence on OTIF as last-mile delivery performance.

OTIF vs OTD and fill rate

OTIF is often confused with related metrics such as On Time Delivery (OTD) and fill rate. OTD only measures whether an order arrives on time, while fill rate focuses on quantity fulfilment regardless of timing. OTIF combines both elements, which provides a more realistic view of customer experience and operational performance.

Why OTIF is important

OTIF is more than a reporting metric. It has a direct impact on customer experience, operational efficiency, and financial performance. Because it touches so many parts of the supply chain, even small improvements in OTIF can create measurable business benefits.

Customer satisfaction and trust

Consistent OTIF performance builds confidence. Customers can plan their own operations when deliveries arrive as promised and without shortages. Over time, reliable OTIF performance becomes a competitive differentiator rather than just a basic service expectation.

Supplier and vendor performance management

Many businesses use OTIF to evaluate supplier reliability. A low supplier OTIF can indicate unstable lead times, poor production planning, or weak communication. This makes OTIF a valuable input into supplier reviews, sourcing strategies, and long-term vendor relationships.

Inventory and cost management

OTIF is closely linked to inventory health. Missed OTIF targets often signal inaccurate forecasts, insufficient safety stock, or ineffective replenishment rules. These issues tend to increase costs through expediting, excess inventory, or lost sales.

Supply chain visibility and coordination

Because OTIF spans multiple functions, it encourages cross-functional alignment. Planning, procurement, warehouse operations, and logistics must work from the same data and priorities to maintain strong OTIF performance. This alignment helps reduce silos and improves decision-making speed.

How to calculate OTIF

Although definitions can vary, the basic OTIF calculation is straightforward. What matters most is that the method is clearly defined and consistently applied across teams and partners.

Basic OTIF formula

The basic OTIF formula is

OTIF (%) = (Orders delivered on time and in full ÷ Total orders) × 100

This simple structure makes OTIF easy to track once delivery dates, order quantities, and confirmations are reliable.

Example calculation

Imagine a wholesaler ships 200 orders in a month. Of those, 170 arrive on time and in full, 15 arrive on time but incomplete, 10 arrive late but complete, and 5 arrive late and incomplete. Only the 170 fully compliant orders count towards OTIF.

OTIF = (170 ÷ 200) × 100 = 85 percent

This example shows how quickly OTIF can drop when timing or quantity issues occur, even if most orders are close to meeting expectations.

Differences in OTIF calculation by industry

Retailers, manufacturers, and distributors often calculate OTIF differently, based on how deliveries affect their operations and customers. These differences mean OTIF results should always be interpreted in context rather than compared directly across industries.

In retail, OTIF is usually measured against strict delivery windows and store-specific requirements. For example, a grocery retailer may require deliveries to arrive between 6:00 and 8:00 a.m. so shelves can be stocked before opening. If a delivery arrives at 8:15, it may be counted as not on time, even if the order is complete.

In manufacturing, OTIF is often calculated at line-item or component level rather than per order. A manufacturer receiving 100 components for a production run may classify the delivery as OTIF-failed if even one critical part is missing, because that single shortage can halt production.

In wholesale and distribution, OTIF is typically measured at order level with more flexible delivery windows. A B2B distributor may accept deliveries within a one-day window but still require exact quantities. An order arriving on time with 95 percent of the requested volume would usually fail OTIF due to being incomplete.

OTIF benchmarks and performance

What counts as a good OTIF score depends on industry expectations, customer agreements, and supply chain complexity. Benchmarks should therefore be treated as guidance rather than absolute targets.

What is a good OTIF benchmark?

Many retailers expect OTIF rates above 95 percent, with some large chains targeting 98 percent or higher. In more complex or volatile supply chains, slightly lower benchmarks may be acceptable if performance is stable and improving.

Tracking OTIF over time

OTIF should be monitored regularly, not just reported monthly. Trend analysis helps teams identify whether issues are structural or linked to specific events such as promotions, seasonal peaks, or supplier disruptions.

How to improve OTIF

Improving OTIF requires coordinated action across planning, inventory management, execution, and collaboration.

Optimise demand forecasting

Poor forecasts are one of the most common causes of OTIF failure. When demand is underestimated, stockouts occur. When it is overestimated, inventory often ends up in the wrong location. Improving forecast accuracy therefore has a direct and immediate effect on OTIF.

Strengthen inventory policies

Clear safety stock levels, well-defined reorder points, and realistic lead times create a buffer against uncertainty. These policies should be reviewed regularly as demand patterns and supplier performance change.

Streamline warehouse and fulfilment processes

Picking errors, capacity constraints, and inefficient layouts all reduce OTIF. Standardised processes, clear prioritisation rules, and performance monitoring help ensure orders leave the warehouse complete and on time.

Improve supplier collaboration

OTIF performance often depends on upstream partners. Regular performance reviews, shared forecasts, and clear expectations around lead times and quantities reduce surprises and improve reliability over time.

Increase visibility with real-time data

When teams can see inventory levels, open orders, and inbound deliveries in real time, they can act before issues escalate. This shifts OTIF management from reactive problem-solving to proactive control.

Align teams around service level targets

OTIF improvements stall when departments optimise locally rather than globally. Aligning KPIs and incentives ensures service levels, costs, and working capital are balanced across the organisation.

Common challenges with OTIF

Even well-established supply chains struggle to maintain consistently high OTIF performance. The challenges are often systemic, cutting across data quality, process alignment, and the ability to manage uncertainty.

| OTIF challenge | What it means in practice | Why it impacts OTIF |

| Misaligned definitions | Teams or partners interpret “on time” and “in full” differently, such as whether early deliveries or partial shipments are acceptable. | Inconsistent definitions lead to unreliable OTIF reporting and unclear performance signals. |

| Data inconsistencies | Order dates, promised delivery dates, and shipment confirmations are inaccurate or spread across disconnected systems. | Poor data quality undermines OTIF calculations and delays corrective action. |

| Limited cross-functional alignment | Sales, supply chain, and logistics teams prioritise different objectives such as revenue, cost, or speed. | Conflicting goals increase the risk of late or incomplete deliveries. |

| Inflexible inventory policies | Safety stock, reorder points, or lead times are not updated as conditions change. | Rigid policies increase exposure to stockouts and last-minute expediting. |

| Managing disruption and volatility | Supplier delays, transport issues, or sudden demand spikes occur unexpectedly. | Without buffers or contingency plans, small disruptions quickly turn into OTIF failures. |

Addressing these challenges requires more than local fixes. Clear definitions, reliable data, aligned incentives, and adaptable planning processes are essential for turning OTIF into a controllable performance driver.

OTIF and technology

Technology plays a growing role in maintaining and improving OTIF performance. It enables better decisions rather than simply faster reporting.

ERP and inventory management systems

Integrated systems bring together demand data, inventory levels, and order information in one place. This reduces manual errors and improves planning accuracy.

Advanced analytics and AI

Predictive analytics can identify OTIF risks before they occur by highlighting unusual demand patterns, changing lead times, or capacity constraints. Over time, these tools help organisations learn from past performance.

Real-time tracking and alerts

Live shipment tracking and exception alerts allow teams to intervene early when delays or shortages arise. This supports faster resolution and more proactive customer communication.

Frequently asked questions about OTIF

What is the meaning of OTIF?

OTIF means On Time In Full. It measures whether customer orders are delivered by the promised date and with the full, correct quantity.

How is OTIF calculated?

OTIF is calculated by dividing the number of orders delivered on time and in full by the total number of orders, then multiplying by 100.

Is OTIF a KPI?

Yes. OTIF is a widely used key performance indicator in supply chain and logistics management.

What is a good OTIF rate?

Many organisations target OTIF rates above 95 percent, although acceptable benchmarks vary by industry and customer requirements.

OTIF vs OTD: what’s the difference?

OTD measures only delivery timing. OTIF measures both delivery timing and order completeness, making it a more comprehensive service metric.

What is a strong OTIF?

Strong OTIF performance reflects accurate planning, disciplined execution, and effective collaboration across teams and partners.