Running out of stock is costly. Holding too much inventory is just as risky. The reorder point sits between these two extremes. It tells you exactly when to place a new order so stock arrives before you hit zero. When it is set correctly, the reorder point helps you maintain service levels, control cash flow, and reduce operational stress.

In this guide, we explain what a reorder point is, why it matters, and how to calculate it step by step. We also look at optimisation techniques, common risks, and how inventory management software supports reorder point planning.

What is a reorder point?

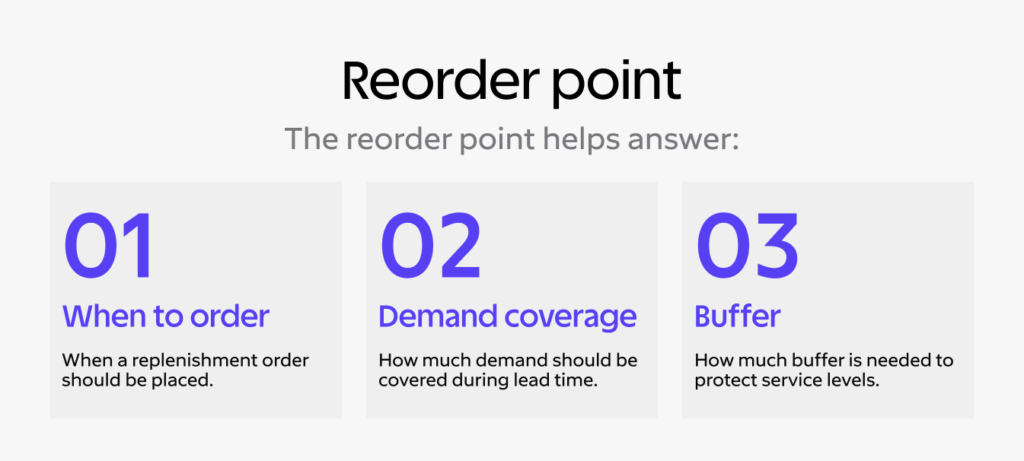

A reorder point is the inventory level at which you should place a replenishment order. It is calculated to ensure that new stock arrives just as existing stock is about to run out, taking supplier lead time into account.

In practical terms, the reorder point answers one critical question: when should I reorder?

It is important not to confuse the reorder point with safety stock. Safety stock is the buffer you hold to protect against uncertainty in demand or supply. The reorder point is the trigger that tells you when to act. In many cases, safety stock is included within the reorder point calculation, but the two concepts serve different purposes.

A well-defined reorder point helps you avoid stockouts without tying up unnecessary working capital in excess inventory.

Why reorder point is important

Setting reorder points properly has a direct impact on service levels, costs, and supply chain stability.

Prevent stockouts and lost sales

When reorder points are too low or poorly maintained, replenishment orders are placed too late. The result is empty shelves, delayed orders, and dissatisfied customers. A reliable reorder point ensures continuity of supply even when lead times are long.

Reduce holding costs and financial risk

Overestimating reorder points leads to overstocking. Excess inventory increases storage costs, insurance, handling effort, and the risk of obsolescence. Accurate reorder points help you hold only what you need, when you need it.

Improve supply chain efficiency and planning

Reorder points create structure in replenishment planning. They align purchasing decisions with real demand patterns and supplier performance, which supports better forecasting, budgeting, and collaboration across the supply chain.

How to calculate reorder point

The classic reorder point formula is simple, but powerful when applied correctly.

Basic reorder point formula

Reorder point = (Lead time × Average daily usage) + Safety stock

Each element plays a specific role.

- Lead time is the time between placing an order and receiving it

- Average daily usage is how much stock you consume per day

- Safety stock protects against variability in demand or supply

This formula assumes that demand during lead time can be estimated with reasonable accuracy.

Determining reorder point without safety stock

In stable environments with predictable demand and reliable suppliers, some businesses calculate reorder points without safety stock.

Reorder point = Lead time × Average daily usage

This approach works only when demand variability is low and service level requirements are modest. In most real-world supply chains, relying on this method alone introduces unnecessary risk.

Determining reorder point with safety stock

Including safety stock makes the reorder point more robust.

For example, if you sell 20 units per day, have a lead time of 10 days, and hold 50 units of safety stock, the calculation looks like this:

- Lead time demand: 20 × 10 = 200 units

- Reorder point: 200 + 50 = 250 units

When on-hand inventory reaches 250 units, a replenishment order should be triggered.

Using reorder point calculators and spreadsheets

Many teams start with Excel-based reorder point calculators. These can be useful for small assortments or initial analysis, but they become difficult to maintain as SKU counts grow.

Spreadsheets struggle with changing lead times, seasonality, multiple locations, and frequent demand updates. This is where dedicated inventory management software becomes essential.

Reorder point formula explained

The simplicity of the formula hides several important assumptions. Understanding them helps you avoid common mistakes.

Lead time variability

Lead time is rarely fixed. Supplier delays, transport disruptions, and order batching can all increase variability. When lead times fluctuate, safety stock levels should be adjusted accordingly.

Demand variability

Average daily usage smooths demand over time, but real demand often fluctuates. Promotions, seasonality, and changes in customer behaviour all affect consumption rates. Ignoring this variability leads to reorder points that are either too aggressive or too conservative.

Multiple suppliers or locations

When items are sourced from multiple suppliers or stocked across several locations, reorder points often differ by supplier or site. A single global reorder point can hide local risks and inefficiencies.

Reorder point planning and optimisation

Calculating a reorder point once is not enough. Effective inventory management requires continuous review and optimisation.

Aligning reorder point with EOQ

The reorder point defines when to order. The Economic Order Quantity defines how much to order. Used together, they create a balanced replenishment policy.

EOQ focuses on cost efficiency by balancing ordering and holding costs. The reorder point ensures timing accuracy. When these two are aligned, replenishment becomes both reliable and cost-effective.

Periodic review and updates

Reorder points should be reviewed regularly. Changes in demand patterns, supplier performance, service level targets, or product lifecycles all require recalibration.

For fast-moving items, monthly or even weekly reviews may be appropriate. For slow movers, quarterly reviews are often sufficient.

Automated systems and alerts

Manual monitoring of reorder points does not scale. Automated inventory systems track stock levels continuously and trigger alerts or orders when reorder points are reached. This reduces human error and ensures consistency across large assortments.

Risks of poorly defined reorder points

Reorder points influence both availability and cost. When they are not set correctly or are left unchanged as conditions evolve, they introduce avoidable risk into inventory planning. These risks typically fall into two categories: ordering too early or ordering too late. Both scenarios have operational, financial, and customer-facing consequences.

The table below outlines the most common risks associated with poorly defined reorder points and explains how they affect the business.

| Reorder point issue | What happens | Business impact |

| Reorder point set too high | Orders are triggered earlier than necessary, increasing inventory on hand | Higher holding costs, tied-up working capital, increased risk of obsolescence |

| Reorder point set too low | Replenishment orders are placed too late to cover demand during lead time | Stockouts, lost sales, delayed deliveries, reduced customer satisfaction |

| Reorder point not reviewed regularly | The reorder point no longer reflects current demand or lead time conditions | Frequent manual overrides, planning inefficiencies, reduced trust in inventory data |

| Ignoring demand variability | Average usage is applied without accounting for fluctuations | Overreaction to short-term demand changes or exposure to unexpected spikes |

| Ignoring lead time variability | Lead times are treated as fixed despite supplier or transport volatility | Increased risk of late arrivals and emergency purchasing |

When these issues persist, teams often compensate by expediting orders, overriding system recommendations, or relying on gut feeling rather than data. Over time, this reactive behaviour undermines planning discipline and makes inventory performance harder to control.

Regular reviews, clear ownership, and automated recalculation help ensure reorder points remain aligned with real demand, supplier performance, and service level targets.

FAQ

What is the formula for reorder point in EOQ?

The reorder point formula used with EOQ is:

(Lead time × Average daily usage) + Safety stock.

EOQ determines order quantity, while the reorder point determines order timing.

What is EOQ and ROP?

EOQ stands for Economic Order Quantity and defines how much to order. ROP stands for Reorder Point and defines when to order.

How do you calculate reorder level?

Reorder level is another term for reorder point. It is calculated using expected demand during lead time, with or without safety stock.

How often should reorder points be updated?

Reorder points should be reviewed whenever demand, lead times, or service level targets change. Many businesses review them monthly or quarterly.

Can reorder points be automated in inventory software?

Yes. Modern inventory management systems automate reorder point calculations using real-time data, improving accuracy and reducing manual work.