The Pareto Principle, often called the 80/20 rule, is a concept that states that a small proportion of inputs typically generates a large proportion of results. In practical terms, it means that roughly 20 percent of causes often drive around 80 percent of outcomes. In business, operations, and supply chains, this way of thinking helps teams focus effort where it matters most, instead of spreading resources too thinly.

This guide explains what the Pareto Principle is, where it comes from, and how to apply it in practice, with clear examples from productivity, inventory management, and operations.

History and origin of the Pareto Principle

The Pareto Principle is named after Italian economist Vilfredo Pareto. In 1896, Pareto observed that roughly 80 percent of Italy’s land was owned by about 20 percent of the population. He later noticed similar uneven distributions in other areas of economics and society.

Over time, researchers and practitioners realised that this pattern appeared far beyond wealth distribution. It showed up in manufacturing defects, business performance, customer behaviour, and time management. As a result, the idea became known as the Pareto Principle, the 80/20 rule, or sometimes the law of the vital few.

Understanding the Pareto Principle in simple terms

At its core, the Pareto Principle says that not all inputs are equal. A minority of actions, products, or customers usually creates the majority of outcomes. This imbalance is common in complex systems where effort and results are not evenly distributed.

The ratio is not meant to be exact. It does not always have to be precisely 80 and 20. Instead, it highlights the idea that some factors matter far more than others. A common misconception is that the remaining 80 percent can be ignored, which is rarely true. The principle helps prioritise, not justify neglect.

Real-life examples of the Pareto Principle

The Pareto Principle shows up in many everyday business situations and helps explain why focusing on everything equally often leads to poor results.

In sales, a small group of customers often generates most of the revenue. In manufacturing, a handful of defects may cause the majority of quality issues. In customer support, a limited number of issues usually drives most incoming tickets. In productivity, a few key tasks often deliver most of the value created in a day or week.

In inventory and supply chain contexts, the pattern is especially clear. A small share of SKUs typically accounts for most sales volume, profit, or service level risk. These items deserve more attention in forecasting, replenishment, and supplier collaboration than slow-moving or low-impact products.

How to apply the Pareto Principle

Applying the Pareto Principle works best when it is grounded in data rather than assumptions.

- Define the result you want to improve

Identify the outcome that matters most, such as revenue, cost reduction, service levels, delays, or stock availability. - List the factors that influence that result

This could include products, customers, suppliers, locations, processes, or tasks, depending on the context. - Rank those factors by impact

Use data to sort each factor from highest to lowest impact. This often reveals that a small number of inputs drives most of the result. - Focus on the vital few

Once these high impact areas are visible, teams can prioritise time, budget, and attention on what truly moves the needle.

This approach turns the Pareto Principle into a practical decision-making framework rather than a theoretical concept.

How the Pareto Principle supports ABC analysis in inventory control

The Pareto Principle is the foundation of ABC analysis in inventory management. While the Pareto Principle explains the pattern, ABC analysis translates that insight into an operational control framework.

ABC analysis starts by ranking inventory items by impact, most commonly annual consumption value, which combines demand volume and unit cost. When items are sorted this way, the familiar 80/20 pattern often appears.

Items are then grouped into three categories.

- A items represent the vital few and require tight forecasting and frequent review.

- B items have moderate impact and balanced control policies.

- C items form the long tail and are managed with simpler rules.

By aligning effort with impact, ABC analysis helps inventory teams improve control, reduce risk, and scale planning processes more effectively.

Tools and techniques for using the Pareto Principle

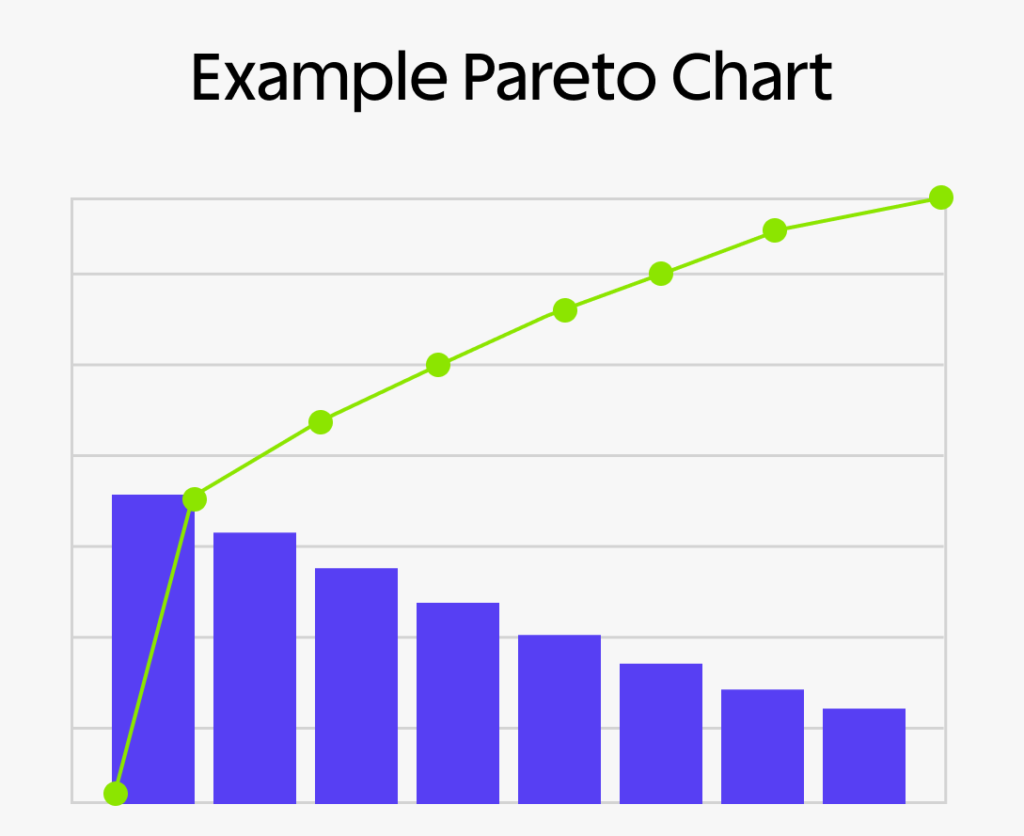

One of the most widely used tools for applying the Pareto Principle is the Pareto chart.

A Pareto chart is a visual tool that combines a bar chart and a cumulative line. The bars show individual factors ordered from highest to lowest impact, while the line shows how much of the total result is accounted for as each factor is added.

This makes it easy to see where the vital few sit and where diminishing returns begin. In inventory management, Pareto charts are often used to visualise which SKUs drive most inventory value, demand, or service level risk.

Benefits of using the Pareto Principle

When applied thoughtfully, the Pareto Principle improves focus, supports better use of resources, and simplifies decision-making. It helps teams prioritise effectively instead of spreading effort evenly across low and high impact activities.

Common misconceptions and limitations

The Pareto Principle is a guideline, not a law. The 80/20 split varies by context and changes over time.

Oversimplification is a common risk. The goal is not to ignore the remaining 80 percent, but to manage it proportionately while concentrating effort where it delivers the greatest return.

Frequently asked questions

What is Pareto’s principle in simple words?

It means that a small number of causes usually creates most of the results.

What are real examples of the 80/20 rule?

Examples include a few customers generating most revenue, a small number of defects causing most quality issues, or a handful of SKUs driving most sales.

What is Pareto analysis in simple terms?

Pareto analysis is a way of ranking factors by impact to identify what matters most.

How is the Pareto Principle used in inventory management?

It helps identify which products drive most value or risk, forming the basis for prioritisation methods like ABC analysis.

How can the 80/20 rule improve productivity?

By focusing effort on the tasks that deliver the greatest results, rather than treating all work as equally important.