Effective supply chains are built on preparation, not guesswork. In this guide, we explore how demand planning helps businesses align forecasting, inventory, and operations to stay ahead of demand, avoid waste, and improve profitability.

Demand planning: A simple definition

Demand planning is the process of forecasting future customer demand to ensure products are available in the right quantity, at the right time, and in the right place. It combines data analysis, forecasting models, and cross-functional collaboration to align supply with expected demand.

In practice, demand planning pulls insights from historical sales, market trends, promotional activity, and real-time data to build a plan that informs procurement, production, and distribution. It aims to balance supply with demand while minimizing excess inventory and avoiding stockouts.

Demand planning vs. forecasting: What’s the difference?

While often used interchangeably, forecasting and demand planning are not the same. Forecasting involves estimating future demand using statistical models and historical data. It provides a numerical projection based on past trends.

Demand planning, on the other hand, builds on forecasting by integrating business inputs and adjusting for known variables such as promotions, seasonality, and new product launches. It incorporates supply chain constraints, lead times, inventory policies, and financial goals to generate an actionable plan.

Think of forecasting as the raw prediction and demand planning as the strategic plan that makes the prediction actionable.

Why demand planning matters for your business

Every business that manages stock relies on demand planning to stay competitive. Without it, companies either hold too much inventory or not enough. Here’s why demand planning is essential:

- Reduces excess inventory: Free up working capital and lower storage costs by keeping stock levels aligned with actual demand.

- Prevents stockouts: Maintain high service levels by ensuring the right products are available at the right time.

- Improves supply chain visibility: Demand planning provides clarity for procurement, production, and logistics teams.

- Boosts forecasting accuracy: By refining forecast inputs and incorporating cross-functional knowledge, planning becomes more precise.

- Strengthens vendor relationships: Suppliers can deliver more reliably when they have visibility into your upcoming needs.

- Supports strategic growth: With better insight into customer behaviour and market demand, businesses can expand more confidently.

Companies that adopt structured demand planning can respond more effectively to market volatility, seasonal swings, and disruptions.

Key elements of effective demand planning

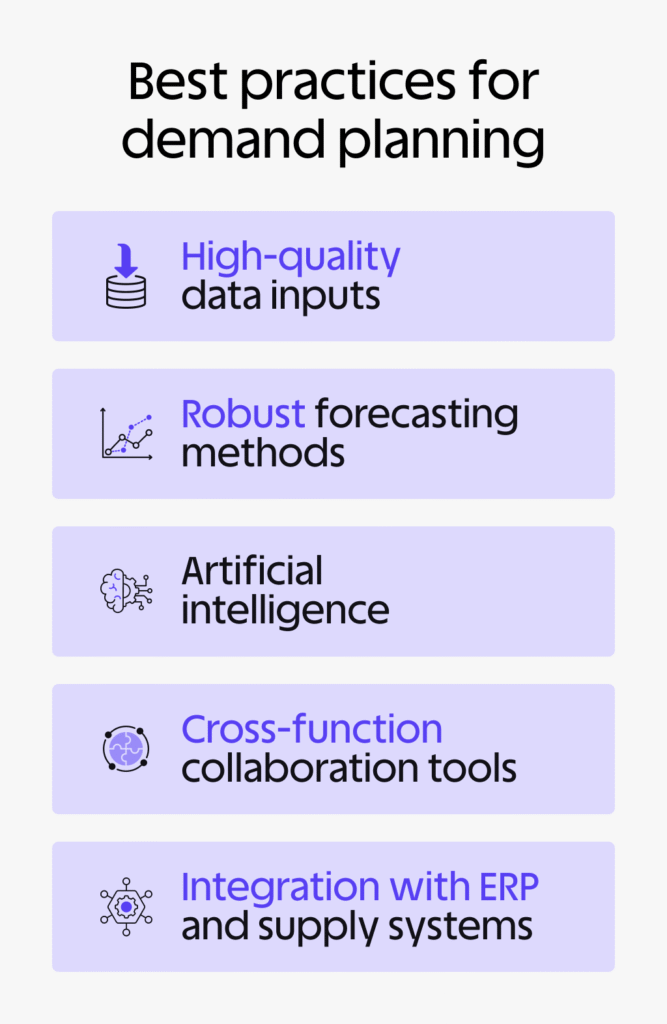

High-quality data inputs

Successful demand planning begins with data integrity. Clean, complete, and up-to-date data enables more reliable forecasting and planning. Key inputs include:

- Historical sales data

- Seasonal trends

- Promotion calendars

- New product introductions

- External market indicators

- Point-of-sale (POS) or channel sell-through data

- Inventory levels and lead times

But having data is not enough. It must be structured, accessible, and decision-ready. Smarter supply chain data makes it easier to identify patterns, track supplier performance, and make timely adjustments. For more on this, see our blog on smarter inventory and supply chain data. , track supplier performance, and make timely adjustments. When data is centralised and shared across departments, teams gain a single source of truth that improves collaboration and alignment.

Poor data leads to poor decisions. Inaccurate stock records, outdated lead times, or inconsistent naming conventions can skew forecasts and lead to costly miscalculations. In contrast, streamlined, reliable data allows for:

- Faster and more accurate forecasting

- Better visibility across the entire supply chain

- Targeted inventory optimisation

- Data-driven conversations between teams and suppliers

Data is the foundation of demand planning. Investing in better supply chain data pays dividends across forecasting accuracy, operational agility, and long-term growth.

Data should flow seamlessly across departments and systems to support collaborative planning. Inaccurate or siloed data undermines the entire process.

Clear forecasting methods

Forecasting techniques vary depending on business size, product complexity, and market dynamics. Common methods include:

- Time series models: Moving averages, exponential smoothing, and ARIMA are best suited for stable, seasonal trends.

- Causal models: Regression-based models that incorporate external drivers such as marketing campaigns, pricing, economic shifts, or weather patterns.

- Machine learning models: Algorithms that use massive datasets to detect non-linear trends and interactions. These models continuously learn and improve as new data is introduced.

While selecting the right method is important, tailoring the forecast to the SKU level is critical. Each SKU behaves differently depending on customer preferences, sales channels, seasonality, and product lifecycle. A blanket forecast applied across categories or product lines can easily miss these nuances.

By generating individualized forecasts at the SKU level, businesses:

- Capture microtrends that affect specific items

- React faster to demand shifts in niche or volatile SKUs

- Minimize overstock of slow-movers and understock of bestsellers

- Improve accuracy by aligning planning granularity with actual customer behaviour

In short, SKU-level forecasting provides the precision needed to execute effective inventory strategies. It’s the difference between broadly estimating demand and managing it with clarity and control.

Scenario planning capabilities

Scenario planning is a critical component of resilient demand planning. It allows businesses to test different assumptions and prepare for uncertainty.

Examples of scenarios to test include:

- A sudden increase in demand due to a marketing campaign

- A supplier delay impacting lead times

- An economic downturn affecting consumer behaviour

Simulating these situations helps businesses develop backup plans and set thresholds for intervention.

Technology & integration

Modern demand planning requires more than spreadsheets. Integrated planning tools bring data together, automate calculations, and enable real-time collaboration. A strong system should:

- Connect to ERP, CRM, WMS, and POS platforms

- Offer multiple forecasting models and AI-driven suggestions

- Support exception alerts and version control

- Provide dashboards for demand planners, finance, and operations

Integration ensures that every team works from the same data, leading to faster decision-making and fewer errors.

How to implement demand planning in your supply chain

Best practices

Implementing demand planning isn’t just about installing software. It requires cultural and process shifts. Here are key steps:

- Start with a pilot: Select a product category or region to test the process. Build early wins and learn what works.

- Build cross-functional alignment: Include stakeholders from sales, marketing, finance, and operations. Demand planning isn’t a solo activity.

- Standardize data sources: Ensure everyone uses the same metrics and definitions.

- Define clear ownership: Assign accountability for forecasts, inputs, and overrides. Transparency supports trust in the numbers.

- Create a review cadence: Monthly or quarterly S&OP (Sales and Operations Planning) meetings help refine forecasts and align plans.

- Invest in training: Equip teams with the skills to use demand planning tools effectively.

- Measure performance: Track forecast accuracy, bias, and other KPIs to improve over time.

The goal is to build a repeatable process that improves continuously as your team gains experience.

Demand planning tools & features to look for

Forecast modelling & scenario analysis

Look for platforms that support different forecasting approaches, from basic linear models to AI-powered forecasts. Scenario simulation tools should allow planners to tweak assumptions and model outcomes quickly.

Cross-functional collaboration tools

Demand planning touches multiple teams. Your system should facilitate collaboration by:

- Sharing assumptions

- Logging overrides and rationale

- Providing version history

- Supporting comments or annotations

This transparency improves trust in the forecast and encourages engagement.

To truly unlock value, the tool should support Sales and Operations Planning (S&OP) by bringing commercial and operational teams together in one shared environment. Effective collaboration allows:

- Sales to communicate market intelligence and campaign activity

- Operations to align supply and production planning accordingly

- Finance to monitor the financial impact of different demand scenarios

- Leadership to make confident, cross-functional decisions based on a shared view

The right technology enables more than just data sharing—it enables structured conversations, accountability, and alignment across functions. This turns demand planning from a siloed task into a core business process that drives accuracy, agility, and performance. Learn more in our post on S&OP best practices. that drives accuracy, agility, and performance.

Integration with ERP and supply systems

Integration reduces manual entry and ensures accuracy. A good demand planning tool syncs with:

- ERP systems (for real-time inventory and order data)

- CRM (for customer insights)

- POS systems (for retail sales visibility)

- Supplier platforms (for lead times and capacity)

The right demand planning technology should integrate seamlessly with almost any ERP system, whether you’re using SAP, Microsoft Dynamics, Oracle NetSuite, or a more niche industry-specific platform. This flexibility ensures that your planning software fits into your existing tech stack without requiring heavy customization or manual workarounds.

With seamless ERP integration, data flows in real time, enabling planners to base decisions on the most current inventory, sales, and procurement information. It also eliminates data silos, reduces errors, and gives every stakeholder access to a single version of the truth. This is critical for maintaining alignment across departments and driving supply chain agility.

When systems talk to each other, planning becomes more dynamic, efficient, and responsive.

Choosing the right demand planning software

The best software for you depends on your company size, complexity, and planning maturity. But universally, you should look for:

- Ease of use: Intuitive dashboards and clear workflows encourage adoption

- Scalability: Supports growth in product lines, regions, and users

- Strong support: Access to onboarding, training, and expert assistance

- Flexibility: Customizable metrics, models, and reports

- Real-time insights: Live updates to reflect new data and changes

You should also consider how well the software supports end-to-end supply chain visibility. A great demand planning solution is more than a forecasting tool—it’s a foundation for supply chain alignment. It should help you:

- Connect demand forecasts with purchasing and replenishment plans

- Optimize safety stock and reorder points dynamically

- Improve supplier collaboration with forward-looking visibility

- Enable scenario planning tied to inventory and financial goals

For growing businesses, a dedicated demand planning platform also reduces dependence on internal IT resources. Rather than building and maintaining your own planning models in spreadsheets, you gain access to proven functionality out of the box. That frees up time for strategic decision-making and cross-functional alignment.

Ultimately, the right tool empowers your team to act with confidence and speed—and sets you up to scale efficiently as your supply chain complexity increases. See our guide on why a supply chain platform should be in your 2025 budget.

How demand planning helped Birlea

Birlea, a UK-based furniture wholesaler, was experiencing frequent stockouts and delivery delays due to demand fluctuations. The team had limited visibility across their supply chain, and planning relied heavily on manual spreadsheets.

With AGR’s demand planning and forecasting software, Birlea transformed its approach to inventory management. They gained real-time visibility into sales trends, improved forecast accuracy, and aligned purchasing with true demand. As a result, they:

- Reduced overstocks and improved warehouse space utilization

- Strengthened relationships with suppliers through clearer purchase schedules

- Improved service levels by minimizing delivery issues and late shipments

- Streamlined internal processes and reduced manual work

For Birlea, demand planning went from reactive to proactive. Today, they make better-informed decisions that support growth without compromising efficiency. By reducing their inventory levels, Birlea also freed up more than £500,000 in working capital—savings that could be redirected to more strategic areas of the business.

FAQs about demand planning

What is demand and supply planning?

Demand and supply planning is the process of aligning customer demand with supply chain capabilities. Demand planning estimates future needs, while supply planning ensures that production and procurement can meet those needs efficiently.

How does AI support supply chain demand planning?

AI enhances demand planning by:

- Identifying hidden patterns in large datasets

- Automatically adjusting forecasts based on real-time inputs

- Learning from past errors to improve future predictions

- Reducing manual intervention in complex models

But AI in demand planning goes beyond automation. The most valuable AI-driven systems continuously adapt to new information, helping planners identify shifts in buying behaviour, manage risk more effectively, and respond faster to disruptions.

For example, AI can detect sudden changes in sales velocity and recommend proactive adjustments to safety stock or reorder points. It can also analyse external variables—like economic indicators, weather patterns, or promotional events—that traditional models often overlook. This enables businesses to act not only on what has happened but also on what is likely to happen next.

Importantly, AI doesn’t replace human expertise. Instead, it augments planner decision-making by freeing up time, improving clarity, and surfacing actionable insights. The result is a demand plan that is more dynamic, responsive, and aligned with strategic goals—especially valuable when agility is a competitive advantage. Explore our blog on AI in inventory management for more insights.—especially valuable when agility is a competitive advantage.

What are the best demand planning tools?

Top-rated tools share several core capabilities that make demand planning more effective, efficient, and resilient:

- Forecasting model variety: The best platforms offer a range of statistical and AI-driven models to accommodate different product types, data maturity levels, and planning needs.

- Real-time collaboration: Strong collaboration features—like shared dashboards, annotation tools, and user roles—ensure teams can work together effectively across departments and regions.

- Seamless integrations: Integration with ERP, CRM, and supply chain platforms is essential for reliable data flow and consistency across the organisation.

- User-friendly interfaces: Dashboards should be intuitive and customisable, making it easy for planners to access insights and take action quickly.

- Scalability and flexibility: As your business grows, your tools should adapt—whether that means adding new SKUs, regions, or users.

These tools are important not only for managing demand more accurately, but also for enabling broader supply chain coordination. Effective demand planning software helps:

- Translate complex data into clear, actionable plans

- Maintain agility in the face of market disruption

- Support strategic initiatives like expansion, sustainability, or diversification

- Improve communication and alignment across commercial and operational teams

In an increasingly unpredictable environment, the right toolset gives businesses the clarity and confidence to move forward with purpose and control.

When should you invest in a demand planning system?

You should consider investing in a demand planning system when your current tools and processes no longer support the complexity or pace of your business. Here are some key indicators that it’s time to upgrade:

- Frequent stockouts or overstocks: Inconsistent inventory levels can damage customer relationships and tie up valuable capital.

- Growing product range or market reach: As you expand into new regions or launch more SKUs, the manual effort to manage forecasts multiplies.

- Planning is time-consuming and error-prone: If teams are spending hours updating spreadsheets and reconciling data from different systems, you’re losing efficiency.

- Lack of coordination across departments: Misalignment between sales, marketing, operations, and finance leads to missed opportunities and avoidable costs.

- Reactive decision-making: If your team is constantly playing catch-up instead of planning proactively, it’s a clear sign your tools aren’t keeping up.

- Difficulty adapting to change: When sudden demand shifts, supplier delays, or market trends arise, your system should help you respond—not hold you back.

The earlier you invest in a scalable demand planning solution, the more value you unlock across the supply chain. Instead of relying on backward-looking data and gut instinct, you gain the foresight and structure needed to grow with control and confidence.