A bill of materials, or BOM, is the backbone of manufacturing and inventory management. Whether you’re producing smartphones, bicycles, or packaged foods, you need a complete breakdown of what goes into each finished product. That breakdown is your BOM. This guide will walk you through what a BOM is, the different types, how it supports your supply chain, and how you can build and manage BOMs effectively with AGR.

If you’re looking for a practical understanding of BOMs, along with examples and templates to get started, you’re in the right place.

What is a bill of materials?

A bill of materials is a comprehensive list of raw materials, components, sub-assemblies, and instructions required to manufacture or repair a product. It is often compared to a recipe: it tells you exactly what you need, in what quantities, and in what order.

Each item in a BOM is detailed with part numbers, descriptions, quantities, units of measure, and sourcing information. This ensures consistency and accuracy in the production process. For inventory and supply chain professionals, a BOM is indispensable because it enables forward planning, cost estimation, and efficient procurement.

Single-level vs. multi-level BOM: What’s the difference

Choosing the right BOM structure depends on the complexity of your product and how it’s assembled. Some businesses may only need a flat list of components, while others require detailed layers to capture sub-assemblies and dependencies.

Single-level

A single-level BOM lists only the components directly required to build a product. It’s straightforward and easy to manage for products with minimal complexity. However, it doesn’t provide insights into sub-assemblies, which can make it harder to forecast component demand accurately.

Multi-level

A multi-level BOM (also known as an indented BOM) breaks the product down into assemblies and sub-assemblies. Each level details what components are required and how they relate to the final product. This type of BOM is essential for managing complex products and ensuring that demand forecasts take into account every layer of assembly. In AGR, multi-level BOMs automatically propagate demand for sub-components based on planned demand for finished goods.

Types of BOM

Engineering BOM (EBOM)

Created during the product design phase, the EBOM is typically developed by engineering and product design teams. It represents the product as envisioned by its designers, containing technical specifications, CAD drawings, and design attributes. The EBOM outlines the structure of the product without considering how it will be manufactured or assembled.

This BOM is essential for tracking design changes and for maintaining version control. It plays a critical role in design validation, prototyping, and compliance documentation. However, because it is built for design rather than production, the EBOM must eventually be converted or adapted into a manufacturing BOM before it can be used on the shop floor.

Manufacturing BOM (MBOM)

The MBOM is focused on execution and is used by production teams to assemble the finished product. It includes every component and sub-assembly, along with packaging, fasteners, labels, and instructions for assembly. Unlike the EBOM, it reflects real-world constraints like factory processes, sourcing availability, and batch sizes.

The MBOM is used to drive procurement, scheduling, and production planning. It also aligns directly with inventory and ERP systems, enabling automation of stock orders and quality checks. For businesses using AGR, the MBOM is critical in connecting forecasted demand with actual component requirements across multiple levels of production.

What are bills of materials used for?

Centralised information

A BOM acts as a single source of truth across departments. Everyone from procurement to production to inventory management relies on it for accurate data. This centralisation avoids miscommunication and improves traceability.

Efficient resource planning

By knowing exactly which components are needed, you can ensure timely procurement, avoid stockouts, and reduce lead times. BOMs allow inventory managers to link component demand directly to sales forecasts or planned production.

Cost control

BOMs let you track the cost of each component and monitor how design or supplier changes impact the bottom line. This level of visibility helps you manage margins and avoid cost overruns.

Quality assurance

A structured BOM helps maintain product quality and compliance. It ensures that only approved materials are used and provides an audit trail that can be referenced in case of product issues or recalls.

Example of a BOM

What a BOM typically includes

A typical BOM includes the following information:

- Part number

- Part name

- Description

- Quantity per assembly

- Unit of measure

- Procurement type (make or buy)

- Reference designators (if applicable)

- BOM level (for multi-level structures)

BOM examples: Sporting good and DIY Retailers

Example 1: Sporting goods wholesaler

A sporting goods wholesaler sells a wide variety of individual items—balls, bats, rackets, protective gear, but also sells bundled kits tailored to beginners, intermediate, and advanced players for various sports. These kits are preassembled and marketed as starter sets.

To manage inventory effectively, they use BOMs to structure each kit, treating them as finished products composed of individual sellable SKUs. Each item (e.g., tennis racket, grip tape, carrying case) is tracked independently, while also being rolled up into BOMs representing the different skill-level sets.

This approach allows the wholesaler to track:

- Sales of complete kits

- Independent sales of individual items

- Forecasted demand for each item, whether sold alone or as part of a BOM

- Inventory pressure caused by popular kits consuming large quantities of a specific component

This BOM structure ensures stock is replenished efficiently, avoids stockouts of key components, and supports both kit promotions and individual product sales.

Example 2: Hardware and DIY retailer

A hardware and DIY retailer offers an extensive range of products: individual tools (e.g. hammers, drills), components (e.g. nails, brackets), ready-to-use DIY kits (e.g. shelves, planters), and even fully assembled finished products like birdhouses or benches.

To ensure availability and balance across their inventory, the retailer uses multi-level BOMs for the DIY kits and finished goods. Each BOM includes the necessary tools and hardware, which are also sold individually. For example, a birdhouse kit might include nails, glue, wooden panels, and instructions—all items that are also available separately.

This setup allows the retailer to:

- Track demand and sales of DIY kits and finished goods

- Monitor stock levels for shared components across different products

- Optimise replenishment cycles and avoid bottlenecks caused by a single out-of-stock item

- Provide flexibility in promotions, bundles, and seasonal offerings

By structuring their product catalogue with BOMs, they keep inventory lean, serve diverse customer needs, and reduce the risk of overstock or obsolescence.

Creating bills of materials with AGR

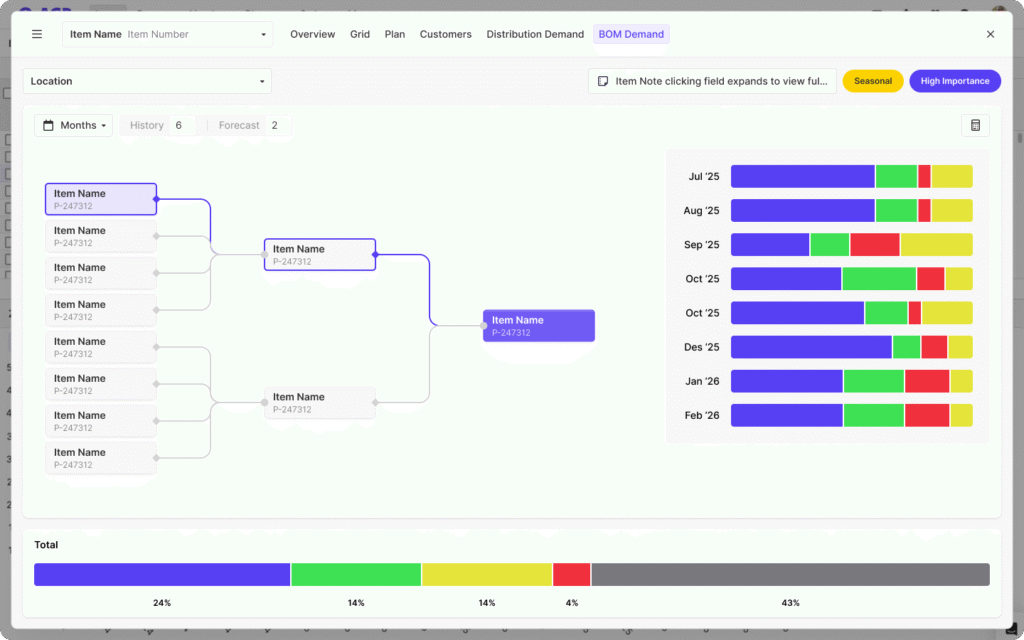

AGR makes building and managing BOMs more efficient through its intuitive item card structure. Each finished product in AGR can be linked to its associated components, forming either a single-level or multi-level BOM. What sets AGR apart is how this functionality integrates seamlessly with demand forecasting.

When demand for a finished product is generated—whether from sales orders, forecasts, or replenishment plans—AGR calculates the component-level demand automatically. This is especially powerful for multi-level BOMs, where sub-assemblies trigger additional demand down the chain. This cascade ensures no part is overlooked, reducing delays and last-minute purchases.

Each level of the BOM is fully transparent and editable within the AGR platform. Teams can view not just what is required, but when it’s required and in what quantities—helping reduce lead times and prevent overstocking.

AGR’s BOM module also supports active maintenance, so updates in one component’s availability or lead time are reflected throughout the plan. If a sub-component is delayed or replaced, AGR can alert planners and update purchase suggestions accordingly.

To dive deeper into how AGR supports multi-level BOMs and real-time inventory planning, see the official documentation: What is a Multi-Level BOM?

Advantages of using bills of materials

BOMs are more than just lists. They are strategic tools that can enhance operational efficiency, reduce risk, and drive better supply chain decisions. A centralised BOM, especially when integrated into a system like AGR, creates visibility and clarity across all departments involved in production and procurement.

Single source of truth

When everyone is working from the same up-to-date BOM, teams avoid costly misunderstandings and duplicate work. A centralised BOM ensures that procurement, planning, and production all rely on consistent and accurate information. This improves accountability and reduces errors caused by version mismatches or siloed communication.

Fewer stockouts and overstocks

By linking component-level data with real-time demand, a BOM helps avoid the twin pitfalls of overordering and underordering. Accurate forecasting tied to BOM structures makes it easier to anticipate component shortages or shifts in kit popularity, which improves customer service and reduces holding costs.

More demand planning control

With BOMs integrated into forecasting tools like AGR, businesses gain greater control over how component demand feeds into supply planning. You can simulate changes, run “what-if” scenarios, and proactively adjust purchasing plans based on changes in demand for finished goods or kits.

Digital BOMs in systems like AGR are accessible anytime, anywhere. No more chasing spreadsheets or siloed documentation.

Who is responsible?

Different stakeholders manage different aspects of the BOM, including:

- Engineers: Responsible for EBOM creation and updates during product design

- Production planners: Maintain MBOMs for manufacturing

- Inventory and procurement teams: Use BOMs for planning, purchasing, and stock control

However, BOMs are only as effective as the collaboration that surrounds them. Accurate data entry, clear documentation, and timely communication between departments are essential to ensure every component is accounted for and every plan is up to date.

For example, if engineering doesn’t update a material specification, or if procurement isn’t notified of a change in packaging requirements, it can lead to delays, stockouts, or even production halts.

Good collaboration hinges on accessible systems, shared visibility, and trust between teams. In this way, managing BOMs becomes not just a task, but a core part of maintaining a resilient, responsive inventory and supply chain strategy.

FAQs about BOMs

What is a bill of materials?

A bill of materials (BOM) is a structured list of the components, materials, and instructions required to build a product. It serves as a blueprint for production and inventory planning. As discussed in the blog, BOMs can be simple, single-level lists or detailed multi-level hierarchies depending on the product complexity.

What is an example of a bill of materials?

In this blog, we share two practical examples. The sporting goods wholesaler uses BOMs to bundle individual SKUs into beginner, intermediate, and advanced sports kits. Meanwhile, the hardware and DIY retailer uses multi-level BOMs to manage everything from individual tools to DIY kits and finished items like birdhouses. These cases highlight how BOMs help balance component-level demand with finished product sales.

What’s the difference between BOM and BOQ?

While a BOM is used in manufacturing to list parts and assemblies for a product, a BOQ (Bill of Quantities) is specific to construction. It outlines materials, labour, and costs for a building project. BOMs focus on assembly and component forecasting, whereas BOQs are geared towards estimating and budgeting for large-scale construction jobs.

What is the difference between SKU and BOM?

A SKU (Stock Keeping Unit) is a unique identifier for an individual sellable item—such as a single tennis racket or a packet of nails. A BOM, on the other hand, represents a collection of such items assembled into a product or kit. For example, in the sporting goods example, each item in a starter kit is a SKU, and the kit itself is represented by a BOM that links those SKUs together.